Questions about the cut quality and consumable life are common when cutting with plasma. How’s my cut quality? Are my consumables lasting long enough? Is there anything I can do to improve my productivity? Unfortunately, there isn’t one simple answer to the above questions because so many factors impact the outcome you will see. Although Hypertherm’s Technical Service Team is happy to help you troubleshoot issues, customers can often achieve the same results by asking the following eight questions.

1. Are You Cutting in The Right Direction?

1. Are You Cutting in The Right Direction?

With standard consumables, the plasma arc spins clockwise as the torch moves forward into the cut. This means the squarest cut angles will be on the right side of the arc. To benefit from this, cut contour shapes in a clockwise direction and holes and other internal features in a counter‑clockwise direction.

2. Are You Following the Cut Charts?

Sounds like a simple question, right? Still, we often come across customers using the wrong settings. Look at your owner’s manual. Refer to the cut charts and make sure you are using the settings listed for the material type, material thickness desired cut quality, and speed you want. The cut charts will tell you what consumables to use, what plasma and shield gas you need and give you the appropriate gas pressure (or flow rates), torch-to-work distance, arc voltage, and cutting speed.

3. Are You Using Good Consumables?

3. Are You Using Good Consumables?

Any type of imperfection on your consumable parts can impact system performance so you want to regularly inspect your consumables and replace them if needed. Though less common, we also sometimes discover customers who have accidentally put the wrong consumables into the torch. If you continue to have cut quality issues, we suggest double-checking the laser-etched part numbers found on each consumable with the numbers in your owner’s manual.

4. Is Your Torch Square to The Workpiece?

Torches can sometimes get knocked out of alignment. If you find that you need to adjust your torch, check to make sure your table and workpiece are levels and that your table slats are not covered in dross. Keep in mind that if the metal plate you plan to cut is bent or warped, it might be impossible to square the torch.

5. Are you holding the right torch to work distance?

Sometimes referred to as a “stand-off,” you’ll want to ensure your torch isn’t too close or far from the workpiece as this will cause angled and rounded cut edges. In addition, if the torch is too close, metal spatter blowing back onto the torch can seriously damage your torch and nozzle. Lastly, don’t forget to routinely adjust the torch to work distance as your consumables wear.

6. Are you cutting at the right speed?

Dross is a great visual clue that lets you know if your cut speed is too fast or too slow. Low-speed dross is the bubbly or globular molten material that collects at the bottom of the cut edge. This kind of dross is easy to remove and flakes off the plate. To eliminate it on future parts, cut faster. On the contrary, high-speed dross causes a thinner bead of molten metal to collect at the bottom of the cut. To fix this, slow down your cutting speed so the arc has time to catch up with the torch.

7. How is your air or gas quality?

If using an air plasma, make sure your air is clean and dry. The same applies to your gas when using oxygen or a multi-gas system. Always use pure, high-quality gas and appropriately sized regulators and gas lines. If a manual purge is required, confirm that the purging cycle was completed. Check to see if gas is leaking or flow is restricted. Ask your gas distributor for help if needed.

8. Does your table need a tune-up?

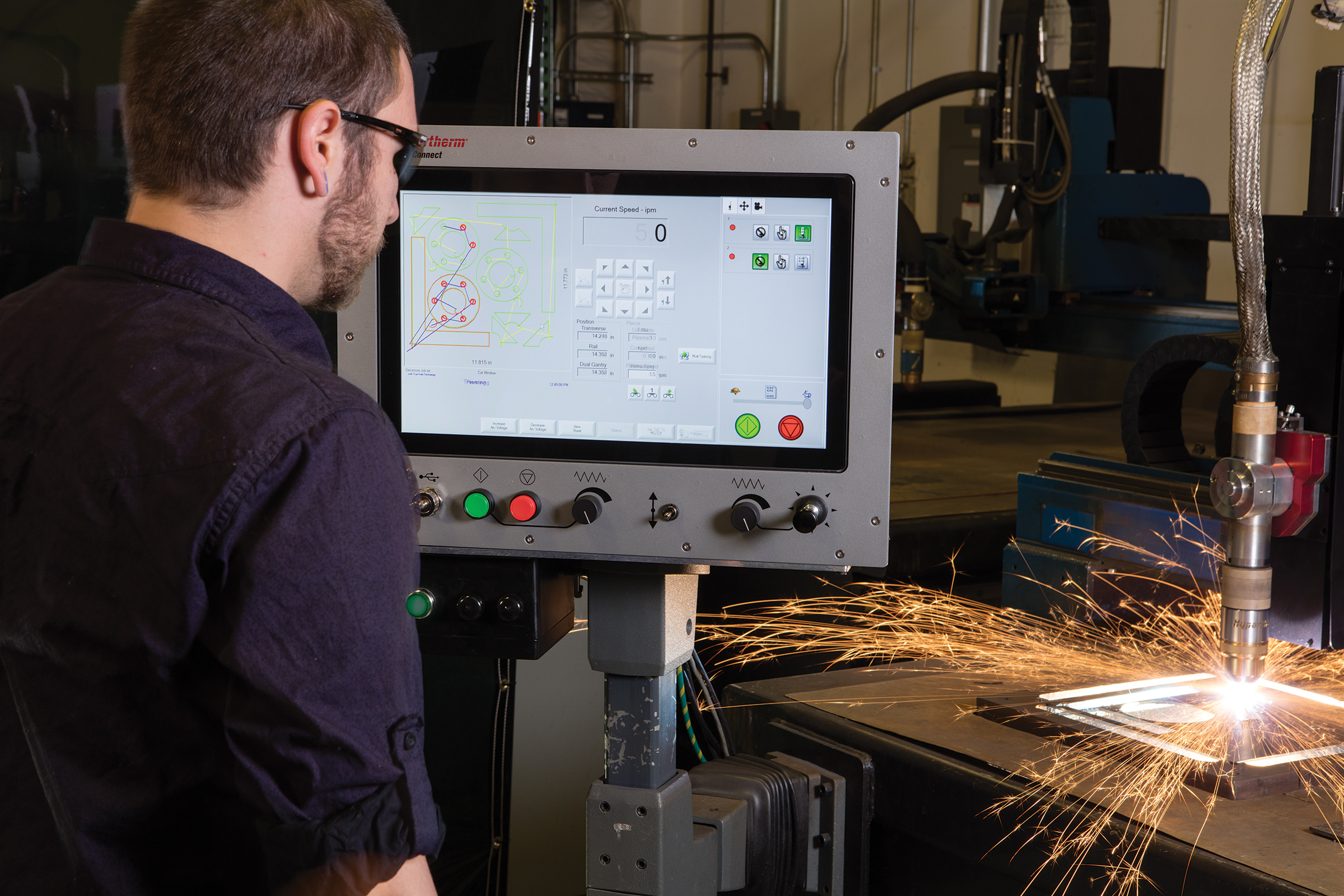

Is the table cutting at the specified speed? Is the torch secured tightly to the table gantry? How is your table motion? Is it vibrating? Often, plasma cutting issues have nothing to do with the plasma itself and instead are caused by poor motion or other table issues. If you’ve run through the preceding seven questions and are still having issues, it might be time to reach out to your table manufacturer.

About Hypertherm

Hypertherm engineers and manufactures industrial cutting products used by companies around the world to build ships, airplanes, and railcars, construct steel buildings, manufacture heavy equipment, and more. Its products include cutting systems, CNCs, and software trusted for performance and reliability that result in increased productivity and profitability for hundreds of thousands of businesses. Founded in 1968 and based in New Hampshire, Hypertherm is a 100 percent Associate owned company, employing more than 1,800 Associates, with operations and partner representation worldwide.