Automation has always come with reshaping labor. Each step in the evolution of automation has led to a redistribution of tasks between man and machine. The overall direction has been transferring ever more tasks to the machines. Now there are two trends on the horizon and they seem to be very different in this regard: Coboting versus Lights-out Manufacturing. What are those? Where will they lead us? And what are the implications for the future of work?

What Is Lights-out Manufacturing?

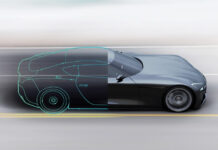

“Lights-out Manufacturing” is a form of production, which is characterized by end-to-end automation that allows for a manufacturing process without the need for direct human intervention at the production site. The term alludes to the notion that fully automated processes could also function in the dark, as no human presence is required. This notion also led to the coining of the term “Dark Factory”. Of course, both are meant metaphorical. In fact, many robots rely heavily on optical sensors, which is why many Dark Factories will be brightly illuminated.

What Is Coboting?

“Coboting” is a kind of production, which is characterized by direct interactive collaboration between humans and robots at a shared production site, with robots responding to human behavior in a situationally meaningful way. The robots capable of such cooperation are named “Cobots”.

Determinants of the Human-Robot Collaboration

With Lights-out Manufacturing and Coboting, we face two apparently contradictory lines of development. While Lights-out Manufacturing is set to eliminate human labor completely from the production process, Coboting is aiming – literally – at a productive cooperation. Which way are we heading? What are the determinants of human-robot collaboration in the future?

Technology has always been both: the enabler of automation and its limiting factor. Till today it is not possible to automate everything. Therefore, it has always been about employing humans and machines in an optimal combination to find the best approach to automation. As with any collaboration, synergy is key. Let both play to their strengths. What are they?

Automats and robots are praised for taking on the four disliked D’s: The dull, the dirty, the drab and the dangerous. Robots can accomplish repetitive, tedious, strenuous, and even dangerous tasks easily. Without exhausting, without tiring, without making errors (at least if all goes well). They score high on speed, precision and constant quality. They do exactly what they are told to do. But they also need to be told exactly. They need to be designed, to be programmed to do one specific task. And that has traditionally been their greatest weakness: Inflexibility. While designed to do something perfectly, it is usually the only thing they can do. Perfection at the cost of perfect inflexibility.

This is where humans shine. To the day humans are unrivaled in their universalistic talent, rooted in a comprehensive set of capabilities: multisensory perception, broad intelligence, emotional sensitivity, motoric abilities, fine motor skills and dexterity. Humans are amazingly talented at critical thinking, problem solving, creativity, flexibility and sensibility.

The Robotic Revolution

The Robotic Revolution

Clearly, humans and robots have very different strengths. Recently, however, these differences diminish somewhat. Sensor technology, artificial intelligence and digitalization are bringing enormous advancements in robotics, increasing flexibility, motor abilities and problem solving capabilities. Cognitive computing might become the brain behind the robot. Even the vision of robots that can manufacture without having to be programmed on a task-by-task basis is about to turn into reality. All of this has two consequences:

Firstly, robots become capable of taking on more tasks that previously required human involvement. While this is the very essence of any automation, this time is different: Robots are not just overtaking individual tasks. In combination with sensors and artificial intelligence, they unite in a new way mechanical abilities with analytical potential. This unleashes manufacturing clout hitherto unknown. These new robots allow the design of smart factories. Thereby they are paving the way to Absolute Automation, the core principle of Lights-out Manufacturing in Dark Factories.

Secondly, robots can collaborate more closely with humans in a truly interactive way. Sensors and artificial intelligence allow for meaningful reactions to the environment. The trend is heading towards truly collaborative human-robotic teamwork. This has the potential to amplify the unique capabilities of humans. It will allow for flexible robot assisted human work, employing robots in completely new domains. This is the essence of Coboting. Ironically, it is the very advancement of robotic capabilities in what have traditionally been considered genuinely human competencies that makes human-robot cooperation possible, thus creating an alternative to Absolute Automation.

The Future of Labor

The implications on labor have to be analyzed on two levels — the company and the market.

Automation will shape the future of labor. And it will do so in different ways, depending on which path automation takes. Dark Factories are based on the idea of Absolute Automation, eliminating any human intervention in the whole production process. At the same time, they supposedly create various jobs to keep the process running: Engineers, software specialists and data scientists are likely to be needed. Coboting on the other hand is based on HumanMachine-Interaction. Envisioned are hybrid working models: Close interactive cooperation between humans and robots shapes the production process itself. In need are skilled laborers with a specific training in cooperating with robots within the production process. They will be guided by Industry 4.0 specialists. Therefore, the transformation will be quite different for companies and the workforce, depending on the path taken.

What will be the effect on the manufacturing labor market? Today the industry is facing two gaps — the shortage of skilled workers to fill vacancies in traditional manufacturing. And the lack of specialized professionals for Industry 4.0. Automation can help bridge the first gap but may deepen the second. Both approaches, Coboting and Absolute Automation, may contribute to that situation in different ways, but the way out is similar for both: Education. The new jobs will be attractive to the tech-savvy generation of digital natives, however, acquiring the needed qualifications takes some time. Therefore, it is likely that we will have to deal with some labor shortage for a while.

What Is the Future of Manufacturing?

What will the future of manufacturing look like? What will prevail, Coboting or Dark Factories? Both, most likely. For quite some time, we will see various forms: Traditional manufacturing, Coboting, fully automated Dark Factories, and everything in between. While being conceptually very different, they are complementary in solving different types of problems. Therefore, it is not about what will prevail. It is about, what to use in a given situation to accomplish a specific goal. Technology will be a limiting factor for a while. In the long run, however, it will become primarily a strategic decision. And one should begin to think of it in this way from today. Because, that is the quintessence: In the Digital Information Age, the approach to automation is even more closely intertwined with the design of the business model. This is one of the situations where it is key to ask the right question. If you ask: What will the future of automation be in my company? Then, you need to answer a deeper question first — what could the business model of my company look like in the Digital Era with Coboting and Dark Factories around?