Maintaining Control Of Gear making

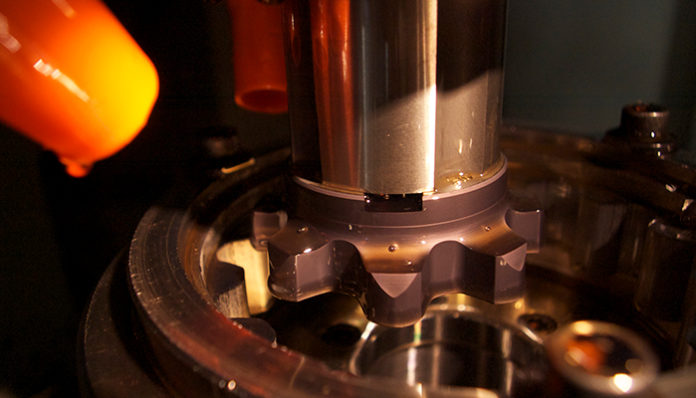

Using CNC technology on advanced machine tools helps the company sell its products worldwide.

Roscoe, Illinois is home to many more gear companies than your average town of 10,000 people, but the reason is obvious. During the peak of the machine tool boom in nearby Rockford, it was critical to have these important components made locally. Over the years, that market has changed and so have the gear companies here, each taking its expertise in other directions to offset the decline in local machine tool building.

Forest City Gear Inc. took a different track to remain competitive globally. As Fred Young, CEO of the company, which was founded in 1955 explains:

“We decided long ago to do two things. First, to make the very best fine and medium coarse pitch gears in the world…

…Second and just as important, we became committed to reinvesting our company’s profits in newer and better machinery, based on the global standards and the ongoing technical advancements made by machine tool builders around the world.”

In the IMD | Industrial Machinery Digest white paper from Siemens you will learn:

- How Siemens CNC has yielded positive impacts on the production.

- The Versatility of Siemens CNC for Gearmaking.

- How Forest City Gear Inc. has been able to manufacture products to compete worldwide.