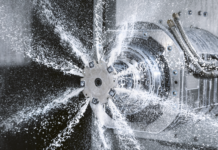

Dillon Full Grip Jaws Securely Hold Workpieces

Available in Sizes and Metals To Suit Virtually Any Application

Dillon Manufacturing full grip jaws available from 6 inches to 24 inches in diameter, with heights of 2, 4, and 6 inches, and metric sizes from 140mm to 630mm in diameter, completely grip workpieces, holding them firmly in place to maintain repetitive accuracy  during high speed machining operations. Available in 356-T6 cast aluminum for a lightweight solution that affords excellent corrosion resistance and good machinability, or 6061 cast iron for a durable, long-lasting solution, or 1018 CR steel for a heat-treatable, easily weldable solution. These pie jaws reduce distortion and provide more friction for drive during turning operations. With close tolerances and concentricity easily maintained, they are ideal for applications such as valves, cylinders, specialty wheels and gears, housings and enclosures, adaptors and connectors, aluminum and steel shells, flanges, retainer rings, and thin-walled parts such as automotive smog control air pump rotors, gas turbine parts, thin-wall tubing and cylinder liners for diesel engines and more.

during high speed machining operations. Available in 356-T6 cast aluminum for a lightweight solution that affords excellent corrosion resistance and good machinability, or 6061 cast iron for a durable, long-lasting solution, or 1018 CR steel for a heat-treatable, easily weldable solution. These pie jaws reduce distortion and provide more friction for drive during turning operations. With close tolerances and concentricity easily maintained, they are ideal for applications such as valves, cylinders, specialty wheels and gears, housings and enclosures, adaptors and connectors, aluminum and steel shells, flanges, retainer rings, and thin-walled parts such as automotive smog control air pump rotors, gas turbine parts, thin-wall tubing and cylinder liners for diesel engines and more.

Dillon full grip top jaws are available to mount either manual or power chucks. They typically ship within 1 week (maximum) from order. All Dillon jaws and related products are Made in the USA.

Dillon Manufacturing, Inc. manufactures a complete line of standard and custom workholding solutions including chuck jaws, chucks, vises, soft jaws, hard jaws, collet pads, and more. They manufacture jaws using 1018, 1045, 4140, 8620, A-2, 6061 aluminum, and stainless steel. All products are made in the USA. For additional information visit www.dillonmfg.com, e-mail sales4@dillonmfg.com, call (800) 428-1133, or write Dillon Manufacturing, Inc., 2115 Progress Drive, Springfield, OH 45505.