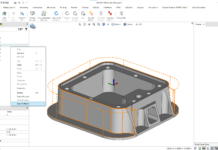

This heat-treating furnace has a maximum temperature rating of 2,000°F and a load capacity of 900 lbs. The workspace dimensions of the furnace are 24” W x 36” D x 18” H and it is designed for air atmosphere applications. The box furnace features an automated actuator to flip the push/pull mechanism on the load table to eliminate the operators need to manually flip it into push position. This option allows the push/pull head to retract from the furnace once the work grid is in the furnace chamber and increase operator safety by removing the need to reach into the hot furnace with a hook to flip the push/pull head and.

The furnace chamber is heated with a radiant heating system the utilizes heavy gauge alloy rod over-bend heating elements mounted along the side-walls and the floor. The furnace temperature is controlled by an Allen Bradley ControlLogix Programmable Logic Controller that includes digital setpoint and display. A Honeywell DC2500 high limit controller disconnects the power to the heating elements and sounds an audible alarm if the temperature exceeds desired set-point.

“This furnace design is a duplicate to a previous order from this customer with the modification of an automated actuator to provides easier loading for the operator. The customer requested a solution to eliminate the need for operators to manually flip the push/pull head when loading or unloading the load into a hot furnace.”

– Bill St. Thomas, Business Development Manager

Unique features of this rod overbend box furnace include:

- Allen Bradley ControlLogix Programmable Logic Controller

- High limit controller to prevent temperature from exceeding set-point

- Automated actuator

- Radiant heating system utilizing rod over-bend heating elements

- Maximum gross workload of 900 lbs

- UL certified control panel