No blueprint ever revealed, no engineer ever designed, a part with burrs. It is only after a process is selected for making a part that the burring issues become obvious. Veteran designers have learned that even when a deburring process is planned, chances are high that additional burr developments will require attention. In most cases, unanticipated deburring is needed in a hurry. A temporary hand-deburring solution is usually the immediate fix until a better solution can be implemented.

Hand Deburring

If you are doing hand deburring as an ongoing solution, then poor quality, inconsistency, a high scrap rate, and employee turnover are likely significant issues for your business. For hand deburring to achieve desirable results, considerable training must be provided. Maintaining a reliable pool of hand deburring workers is tough, and you are always training someone new. James Richards, founder of James Engineering, explained how manufacturers tend to accept hand deburring as a satisfactory fix despite the drawbacks. “I watched a demonstration of a company’s best hand-deburring specialist as they processed an airplane cylinder head. It was impressive to watch; 17 minutes later, the specialist was done. I said, ‘Great! Three cylinder heads an hour with a three-minute turn around and you can do 21-heads a day; Right?’ ‘Oh no,’ was his reply; “We do seven heads a day.”

It is rare to find a person who can maintain production anywhere close to a theoretical or averaged cycle time. On the other hand, the positives of hand deburring are that you can always find a way to complete the job.

Manual Gear Deburring Machines

Manual Gear Deburring Machines

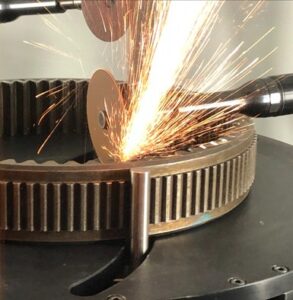

Gear deburring machines require an operator to manually set up each deburring tool. Early models used single tools, usually an air tool holding a 3-inch diameter grinding wheel on a weighted, hinged lever. If the deburring of simple gears is your need, these early machines are still effective. However, since such machines generally use only one tool to chamfer gear teeth, the exit burrs need to be filed off using a manual lathe or similar method, before this deburring method can be used effectively.

By the 1980s, companies such as James Engineering came along and added up to four tools to these manual-machine designs, which enabled more tools to be used, resulting in a quicker cycle time. Removing exit burrs using this new manual-machine design was no longer a separate operation. This multi-tool advancement changed everything.

In the late ‘80s, James Engineering added its automatic wheel-wear compensation control feature and a unique raised-gear holding capability to further distinguish its early manual-machine models. Together, these additions made the flipping of gears an unnecessary step in the manual-machine finishing process.

Gears could finally be removed from a gear cutter and put onto the James Engineering gear deburring manual-machine. Tool number one is manually set up to remove the exit burrs of the gear. Just a few degrees behind this operation, chamfer tools number two and three can be set up to put chamfers on both sides of the gear. Tool number four, an abrasive brush, can be used to remove the micro-burrs of the chamfered gear teeth, completing four operations and producing a completely finished part in a single cycle.

As the early manual-machine deburring systems gained popularity, people found that each tool took up to five minutes to set up, test, adjust the setup and retest, and then run a batch of parts. These machines would run cycles of 15 to 30 seconds a side for gears measuring six inches in diameter or smaller. Larger gears might have a cycle time of a minute per side. These types of manual deburring machines are still used today.

The negative to a manual-machine deburring system is that an operator with skill and knowledge of how to perform the manual setup for each gear type is required. Another drawback becomes clear if you are a job shop or production operation with multiple short-run batches. In these cases, you will spend a significant amount of time each day setting up a manual machine for new parts.

A common scenario is that a business wants to set up six parts each day on a manual machine. Their operator spends 15 minutes setting up the machine, then 10 to 20 minutes getting the setup to produce the quality of part needed by tweaking the setup. On the surface, this timing doesn’t seem bad; but losing three hours to set up the machine out of an 8-hour shift means you’ve lost 37 percent of each day’s production time.

Today, we are in a digital, computer-controlled world where operators just want to download a program and run parts. Not all manual gear deburring machines are the same. Many use pivoting axes, which are difficult to set up to achieve the desired results. Moving a pivot point for multiple axes means you have shifted all the axes of the tool you are trying to set up along multiple planes at once — a complex visual and spatial problem for an operator to solve quickly.

Other machines introduced small openings, which make it difficult to see what is going on during the setup. If this method appeals to you, the best advice is to compare brand features, and do your homework.

Focused Deburring™, Chamfering, and Finishing

Focused Deburring™, Chamfering, and Finishing

It was the introduction of the MAX System™ by James Engineering that gave birth to the phrase, Focused Deburring™. The MAX System™ eliminates the need for skilled operators to manually change setups from one part to another. All the machine operator needs to do is select the correct recipe from the inventory of recipes; press enter; load the part into the machine; then press cycle start. Run one part or 100 parts; select-enter-cycle start and run another one or 100 parts.

To run six different part types during an 8-hour shift, for example, takes less than 30 seconds to set up all six parts. The MAX™ can run six or 60 different parts in the course of one 8-hour shift and only lose a couple minutes total time to select-enter-cycle start as needed.

Once a part has a recipe, you never need to create another one; and every time you run a recipe, the part that is produced is identical. A spur gear only requires five minutes to create a recipe, and anyone can be trained to do it. No CAM Software or even CAD model is required. Everything is done from the MAX System™ machine interface.

Today’s MAX System™ is composed of tool towers attached to the machine’s roof. Each model comes standard with one to four towers, and each can use up to six axes of fully synchronized motion. Each tower can have up to three tools capable of 1,000-ipm rapid travel, which makes quick work of complex motions. Additionally, the machines can be fitted with a 1,000-rpm rotary table. This nets an impressive system where all axes and rotary tables are fully synchronized, and interpolation, threading, and repeating are easily manageable. This configuration enables the maximum amount of work to be performed simultaneously by each tower system and delivers a maximum amount of output in short cycle times.

These upgraded axes give each MAX™ machine a wide, three dimensional tooling range and ability to deburr and finish surfaces no other multi-axes machines can match. In this patented design, all electric servos, ball screws, and linear motions are out of the work area, so toxic nanoparticles cannot affect these components’ daily operations.

The patented tool-head design of the MAX™ delivers precision, computer-controlled working forces behind its perishable tooling media and produces consistent, ultra-price edge and surface finishes. Active axes, along with automatic wheel-wear compensation control, allow a wide range of media to be applied with different, precise forces to every part as each tool head moves over different surfaces, performing multiple, distinct deburring and surface finishing processes. In addition, the technology can create different sized chamfers and edge radii to distinct areas of the same part, and apply these combined functions within a single cycle for precise quality and consistency, at extremely high throughput rates.

Along with its Focused Deburring™, the MAX System™ delivers selective surface finishing for only the part surfaces manufacturers deliberately choose to finish. The MAX™’s selective finishing abilities — to quickly process some part features and completely avoid others, without requiring part masking or special setup adjustments — is a new option for this industry, especially for those who have leaned heavily on abrasive finishing.

Perhaps the biggest misconception of the MAX™ is price. Back to the 1960s and 1970s everyone thought CNC machines would never replace manual mills and lathes for the same reason. Today, manual shops are all but nonexistent. The MAX™ is less expensive than most CNC machines with comparable axes numbers. The MAX™ has begun to take deburring, chamfering, and selective surface finishing by storm, because it does the job faster, better, cheaper, and without requiring skilled operators.

Combining Focused Deburring™, chamfering, and finishing allows the MAX™ to work specific part-features. The advantages realized from Focused Deburring™, Chamfering, and Finishing are: 1) reduced cost-per-part, 2) least amount of energy consumed per part, and 3) greatest number of parts produced per perishable tool use. By precisely deburring and finishing only surfaces you want processed, the MAX™ saves you time, consumables cost, and energy, for MAX™(imum) Efficiency.

Product Specifications

James Engineering revealed an automated alternative to traditional deburring and chamfering methods with its patented 11-axis MAX System™ CNC-type deburring and chamfering machine that includes technology to increase speed and simplify programming, setup, and operation. This machine consists of two, five-axis heads and a C-axis rotary worktable. Servomotors position the heads via an X-Y overhead gantry using hardened, chrome, ground shafts and carriers with multiple, preloaded bearings.

In addition, the MAX System™ features multiple nozzles delivering water-based coolant with a rust inhibitor at 200 gpm to not only keep the part and tools cool during an operation, but also to wash the part and machine work zone. The two heads can perform finishing operations concurrently using various brushes and abrasive tools to minimize overall cycle times. Both of the heads are fully customizable with twelve types of tools available.

One of the main features of the MAX System™ is having the ability to store as many as 100 part programs, referred to as “recipes”. Individual operations can be chained together to further speed programming. The MAX™ is capable of such high precision that the company calls it “Focused Deburring™” so only the part or place on that part that requires finishing operations are touched, ensuring the finished product will meet perfect standards.