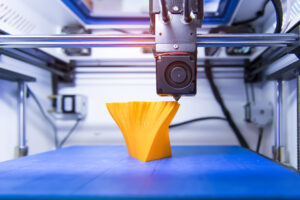

Recent times have shown those in manufacturing and the supply chain that 3D printing – or additive manufacturing (AM) – is becoming a serious and mature manufacturing technology, not only for prototypes but also for small and medium sized series. Here are six key trends which are having a major impact on the 3D printing industry and those using the technology.

1. The New Era: Bigger, Faster, and Cheaper

3D printing/AM technologies are developing quickly, and they are getting bigger, faster, and cheaper. Rising demand for specialized materials to fulfill the required properties of end-parts will continue to drive forward developments in the range and types of options available. The key for the new generation of printers, especially industrial-grade solutions, is their ability to handle a greater range of advanced materials, as this opens the door for businesses to benefit from AM where they previously could not.

Although machine costs remain high, increased print speed is pushing the price of parts down. As more and more businesses switch to 3D printing, these advancements will accelerate. With processes such as dual extrusion, the versatility of 3D printing is growing, and we see uptake of 3D printing in a wider range of industries. Another trend likely to significantly drive development is printing without the use of support structures, which again broadens the range of applications AM can offer. In our eyes the potential for cost and time savings is high.

2. AM as an Integrated Supply Chain Approach

To maximise benefit, manufacturers not only need a large range of printers, but also materials, and importantly, connections with other industry professionals. Furthermore, interoperability between different systems is becoming important to maximise the potential of 3D printing. Automation in production and post-processing as well as an integrated usability will continue to be an important trend in the coming years.

AM can provide a whole new supply chain approach, as part of a holistic and secure platform where the individual steps are combined into one process, from concept to materials, digital inventory, production, and delivery. As manufacturers strive towards Industry 4.0, services offering a fully automated, yet secure, platform will drive this change forward.

3. From Individual Partnerships to an Ecosystem

Partnerships can create mutual benefits and synergies that lead to a greater product for the end-customers. In 3D printing this has proven to be a main enabler to scale industrial production. However, we now see the need for a more holistic collaboration. Standards have to be developed together, printer and post-processing systems should be able to work together; and collected production data could lead to improved printers and materials.

From our own perspective, close collaborations are essential to achieving the best solution. An ecosystem where service providers, material producers and print farms worldwide are connected is the next step to building a better service. Only with close collaborations and permanent exchange can we offer customers the best solutions.

4. Security and Quality Assurance as Part of AM Industrialization

3D printing continues to transform todays industries, with companies adopting the technology for more and more of their needs, thereby giving rise to a more integrated production environment. However, for industrial production, companies have to be assured that their 3D printed parts will meet necessary quality requirements. Moreover, data ownership will play a crucial role. Intellectual property needs to stay in the right hands. We believe that data management will be a huge topic moving forward.

From our own perspective, in terms of quality assurance, we carefully select production partners, check their capability and ensure repeatable fit-for-purpose parts. Further steps are required to ensure design data is kept in the right hands. In addition, we enforce manufacturing parameters by encrypting the data, so the parts can only be produced in the requested amount and material. By collecting manufacturing data and analysing it, mistakes can be detected quickly, improving the process and ensuring all quality requirements are met.

5. Creating a Resilient Supply Chain

5. Creating a Resilient Supply Chain

Yes, we know, this issue has been discussed several times and it was one of the main issues in 2020 and 2021, yet we feel that supply chain disruptions will continue to rock the boat. COVID-19, geopolitical issues like cross border trade disputes, or even something as unforeseen as a ship getting stuck in the Suez Canal have shown the vulnerability of supply chains.

3D printing has already been used in the past as a solution to those problems and we predict use of it will increase. With the decentralization of supply chains and the on-demand production close to the consumer location, the technology enables shorter, stronger and more resilient supply chains.

Physical inventory is the weak point in any supply chain and the fact that parts can be housed digitally rather than in a physical warehouse, eliminates both storage and transportation costs. With a digital warehouse, once a part is ordered, it can be automatically sent to the best fitting, most appropriate production partner based on location, capabilities and capacity. Parts can be produced anywhere. at any time – reducing CO₂ in logistics and improving supply chain resiliency.

6. Driving Sustainability Forward

Demands of end-customers, official regulations and even moral duty, are making sustainable production and supply chains increasingly necessary. This trend is also present in 3D printing, which can – in the right use case – reduce waste during production. By specifically designing a part for 3D printing, it can drastically decrease the weight of the end part, therefore reducing the material needed for production. Moreover, as mentioned above, when using 3D printing as part of an on-demand and decentralised digital warehouse, it could reduce the number of parts in inventory and associated waste, as well as CO₂ emissions during transport.

Looking ahead, we envisage a growing usage of 3D printing as part of companies’ sustainability strategy. To further improve sustainability of the technology, the energy consumption during production has to be reduced, and we are already seeing huge improvements in this area. Moreover, we see a growth of sustainable 3D printing materials such as recycled, reusable, and biodegradable plastics.

About the Author

About the Author

Max Siebert is CEO & Co-Founder of BASF-owned, Replique, which offers an industrial 3D printing platform that enables OEMs to provide parts on-demand anytime and anywhere to their customers through a global, decentralized and secured 3D printing network.