Additive manufacturing is a novel archetype of production technology. It alters the very nature of the production process itself. Its rise is tantamount to a paradigm shift. What is additive manufacturing? What are its advantages, and what are the implications on business strategy?

What is Additive Manufacturing?

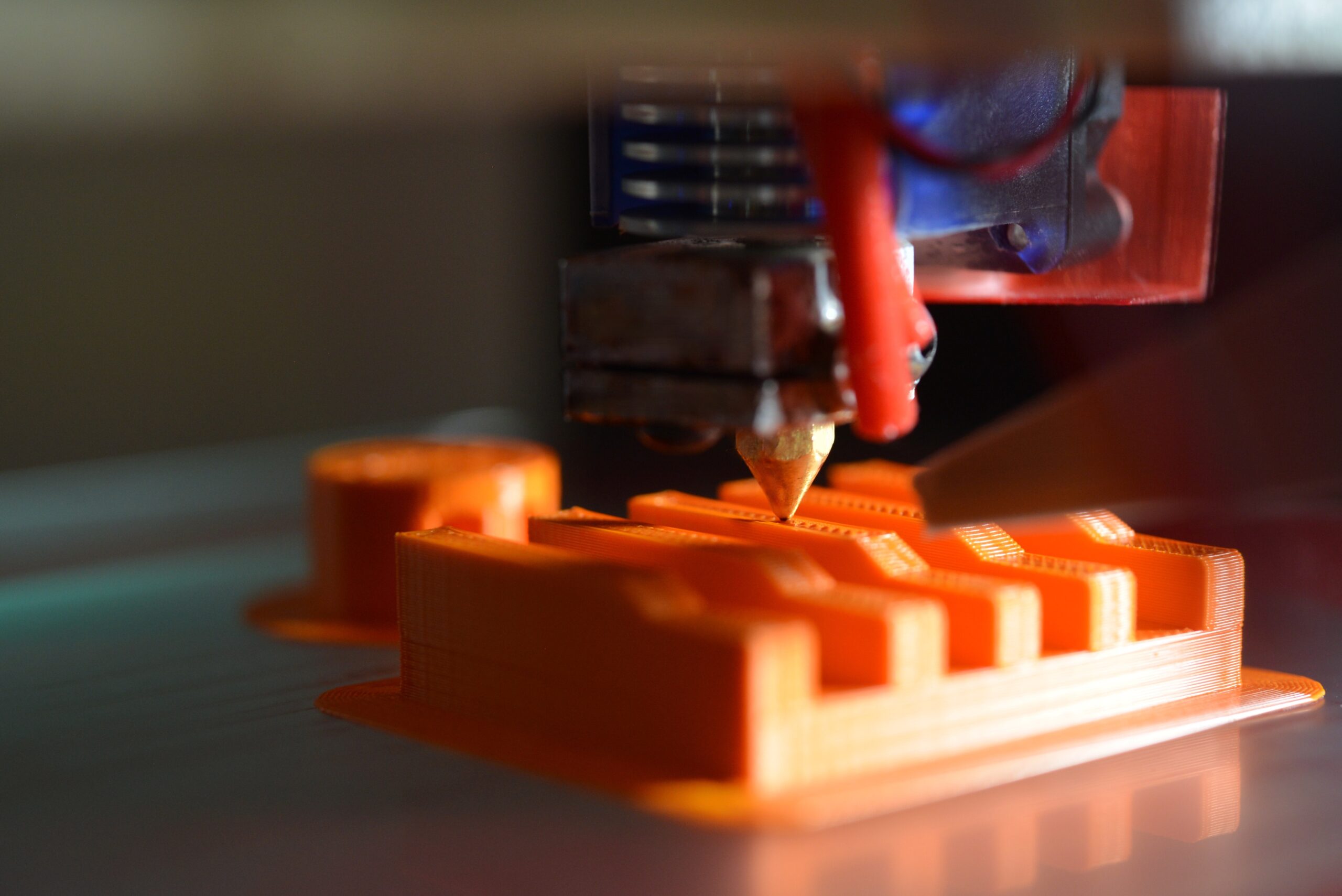

Additive manufacturing is the creation of physical three-dimensional objects by successively joining raw material into a well-specified shape, usually by sequential layering and bonding which is controlled by digital technologies.

Colloquially, additive manufacturing is often referred to as 3D-Printing. Technically that is not entirely accurate, because printing is just one of its forms. Rather, additive manufacturing is an umbrella term for a whole new archetype of production. It describes a wide variety of production technologies. These differ in the type of raw material used, the approach to successive joining, and the technologies to steer the process. The common characteristic of all of those is the Conjunctive Emergence of objects from raw material according to a specified design. That’s why this new archetype of production is often contrasted to Subtractive Manufacturing, where material is taken away to shape the product, for example by hewing, carving, cutting, drilling, milling, filing, and grinding. In contrast, in additive manufacturing Conjunctive Emergence is achieved by technologies like Material Jetting, Material Extrusion, Binder Jetting, Powder Bed Fusion, Directed Energy Deposition, Sheet Lamination, and Vat Polymerization. With those technologies it is possible to process a wide variety of raw materials. Well established is the use of plastics, polymers, metal and ceramics. But today the spectrum is much wider, extending to materials as diverse as concrete and biological tissue. And further materials are explored in research and development.

Advantages of Additive Manufacturing

Conjunctive Emergence has been a dream of humankind, one as old as time. The ability to conjure physical objects out of amorphous material is a notion dating back to ancient legends, an idea that had been attributed to the realms of magic. Now technology has turned magic into reality. Fascinating in itself as it may be, it also bears very substantial advantages. The following overview pointedly details some general advantages that may in principle occur with additive manufacturing. Of course, they do not necessarily manifest in every scenario, and of course there are also disadvantages that have to be taken into account. However, this article is not about individual applications but the general features of this new archetype of technology and the resulting potential to induce transformational change.

Geometric Freedom

The limits of technology are the limits of design – this has always been a fundamental truth of traditional manufacturing. Particularly, in regard to the geometric shape of the product. This restriction is almost entirely lifted by additive manufacturing. Conjunctive Emergence offers geometric freedom. Almost any shape is possible. Forms that could not be created in any other way. This freedom of design comes with the most wonderful of consequences: Allowing new aesthetics. Enabling new physical properties. Facilitating new mechanical characteristics. Engineering new ways of construction. Ultimately, leading to new products, serving needs hitherto impossible to fulfill. Just thinking about healthcare, for example, this is spectacular news.

Product Complexity

Simplification by enabling complexity – geometric freedom has an astonishing impact on product complexity: Allowing the fabrication of more complex parts can result in end products that are more sophisticated yet less complex. With additive manufacturing it is possible to create objects in one piece that would have required assembly of multiple parts otherwise. A work step saved. Quality potentially increased. And it gets even better. 3D-Printers are indifferent as to what shape they print. Complexity is free, after all.

Product Optimization

As an all-round optimizer, additive manufacturing helps in all phases of product optimization: design, production, and improvement. In design, for example, geometric freedom allows components to be optimized for static stability, material use, and weight saving. The production process itself is inherently waste-reducing, as in additive manufacturing only material needed is being used. This is in sharp contrast to Subtractive Manufacturing, which is all about removing excess material, necessarily resulting in waste. And, finally, additive manufacturing is predestined to facilitate incremental improvements: With no product-specific hardware required, there is no upfront investment which makes it possible to include any improvement directly into the ongoing production. Conjunctive emergence allows for Iterative Innovation. Welcome to the world of agile manufacturing!

Precise Reproducibility

Consistency is key, when it comes to quality. And screwing this up gets more likely by the numbers: the number of parts, the number of work steps, and the number of people involved. Additive manufacturing can help to reduce all of them. And in the production process itself it offers precise reproducibility due to computer control, full automation, and the homogeneity of the raw material. Best of all: Reproducibility is an inherent characteristic of additive manufacturing, coming without further cost. Remember that quality consistency is free.

Fixed Cost Effects

Fixed costs and fixed strategy are upfront costs that limit managerial options and have a lock-in effect once a choice is made, whether it’s in regard to a product, a business model, or a strategy. That’s why it is most relevant that additive manufacturing has effects on fixed costs. In principle, besides the 3D-Printer, no further hardware is required. No product specific setup. No mold. No tools. No equipment. This has huge implications. Most importantly, no product specific upfront investment in hardware is required. Idea, design, and plan are the only product specific upfront costs. Furthermore, without the need for a specific setup, there are no setup times. And no specific training is necessary that would be time-consuming. Marginalizing the initial fixed costs of a product paves the way for instant break-even, which is the precondition for single-piece production and small batches. With conjunctive emergence, it makes no difference in the cost of production itself whether two identical pieces are produced or two variants. Variety is free!

Process Simplification

Contra-intuitive as it may sound, a technology as complex as Conjunctive Emergence can result in process simplification. Unitary one-step production simplifies organization, diminishes the need for coordination, reduces product complexity, eliminates compatibility issues, and abolishes the need for assembly. Simplification is enhanced further by digitalization. The production process itself is steered by software. All of this has also an impact on the competence level required: Process management capability and craftsmanship are less important. That is why some use the moniker of little-skill manufacturing – inappropriately, of course, as the skills required in design and handling are advanced.

Digital Native

Additive manufacturing is the digital native among production technologies. All technologies of Conjunctive Emergence are founded on software control. None of them could work without it. While other archetypes of manufacturing need to be digitalized, Conjunctive Emergence is inherently digital. And often it enables unitary one-step production. Both featured combined allow for a seamless integration into a fully digitalized production chain. From dream to data to 3D. Additive manufacturing can serve as an interface between the Digital Infosphere to the physical entisphere. It’s does something unique: Materialize information. This is a most sought-after feature in a digital economy.

Strategic Implications of Additive Manufacturing

Anyone can be quick to conclude the obvious. Tragically, too many leave it at that. Let’s not be one of them. This is always good advice. But in regard to the business implications of additive manufacturing it seems necessary advice.

Additive manufacturing is clearly a most flexible production tool, ideally allowing a lot size of one without upfront cost, fully integrated in the digital workflow. As such it is perfectly suited for prototyping, which was one of its early applications (Rapid Prototyping). It is also optimal for spare parts of outdated products, helping with inventory efficiency, logistics, and time to repair (Rapid Repair). And it is perfect for individual production, that traditionally involved a lot of manual craftsmanship. A typical example is dental prosthesis production. Also mechanical engineering and plant construction is a classical use case (Rapid Tooling). All of those applications are, well, obvious. One should not halt at this conclusion. The colorful bouquet of advantages presented above suggests that they have the potential to unfold implications of greater strategic reach. What are they?

With product-specific fixed cost crushing, break-even shortening and process simplification, traditional entry barriers diminish. With variety becoming free, individualization and mass customization mature into the new normal. With reproducibility, main pillars of competitive advantage break away, like production technology leadership, process perfection, and skill; what really remains is intellectual property rights. With new forms of product optimization, a shift toward agile manufacturing is on the verge. Combined, these trends have the potential to fundamentally reconfigure the competitive landscape. Lower entry barriers entice new players to the market. Process simplification gives smaller companies a chance. And individualization induces a paradigm shift from economies of scale to adaptability.

Beside these changes driven by process innovation, also product innovation is likely to occur. With geometric freedom, freedom of design, and free product complexity the creation of completely new products is possible. Thinking of end-products there will be substitutes, surrogates, and completely new products serving hitherto unaddressed needs. But there will be also new components for existing end-products.

And finally, the rise of additive manufacturing is part of the larger trend of Digital Transformation, which changes the structures and the functional logic of the economy drastically. Digital Transformation reshapes the very foundations of the economy and additive manufacturing is both, a driver of this development as well as an ideal fit for the structures of this new world.

What is the quintessence? Wrapping it up, we observe a combination of process innovation, product innovation, and business model innovation. In combination, they have the potential to alter the functional logic of the industry significantly. The success drivers are likely to shift from economies of scale to adaptability and from perfection of production processes to optimal integration into the value chain in the Digital Era. Amid such revolutionary transformation, many may wonder if there is anything constant to provide guidance. Ultimately one truth always prevails — Economy is about satisfying human needs. Find ways to do that, and you are in business.