Visit the KAAST Machine Tools team for demonstrations of their 22” swing, Fanuc 0i-TF, 25 Hp, vertical lathe; the V-Turn CNC 550. Loaded with live tooling, C-axis, and Renishaw HPRA tool setter, this vertical lathe has a 2-stage transmission with extremely high torque for heavy-machining even tough materials. The 12-tool turret, coolant system, chip conveyor, and automatic lubrication round out this VTL.

Also running at the show will be the KAAST VF-Mills the A 11 L and the D Mini. These VMCs match fast tool changer with a 10,000 rpm CAT40 spindle. Running the newest generation of the Fanuc 0i control systems, these feature extremely robust and solid base frames providing great rigidity, stability, and vibration-free work even with heavy duty cutting.

The C-Turn series engine lathes feature hardened, precision-ground guideways, exceptionally low noise, and a universal gearbox. This allows for cutting the most precise measurements with no need to change gears. KAAST will be displaying both manual and CNC versions of the C-Turn, with the CNC version showcasing conversational programming with the Fagor8055i/A TC control panel that does not require the user to have a prior CNC programming or G-Code background.

Visitors are invited to examine the CNC teach style bed mill designed for small series production and prototyping, the DMV 380 VS CNC. Featuring a drilling and milling head with quiet V-belt drive operation, infinitely variable spindle speed control is paired with automatic spindle sleeve feed (3 steps (with micrometer depth stop). Running the Fagor8055i/A control, operators can upload existing files, write at the machine, or operate manually.

For grinding, the F-Grind AH on display in the KAAST booth offers a grinding spindle which runs in heavy-duty, preloaded angular contact ball bearings and features automatic feed in X/Y/Z. High positioning accuracy of the vertical axis is realized by AC servo motor in conjunction with recirculating ball screw. The demonstration will showcase the AD5 NC control programmable feed of the vertical axis, automatic cross feed of the table, control of the number of passes and various pre-written grinding cycles.

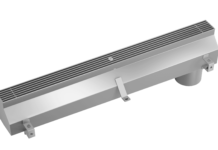

The HBS A 230 will be churning out slices of 9” pipe during the show, demonstrating this fully automatic horizontal band saw’s “set it up and walk away” ability. With automatic material feed and blade breakage sensor, this saw can safely cut for hours without operator intervention.

Angle and plate rolls, presses, and ironworkers will also be on display.

Special pre-show pricing with delivery from the show is available on all machines currently scheduled to be shown. Visit www.KAAST-USA.com/tradeshows for a complete list of machines included and your no obligation pre-show quote.

About KAAST Machine Tools, Inc.

KAAST Machine Tools, Inc. is proud to offer one of the most diverse and extensive line-ups of machine tools in the industry. From mills and lathes to grinders and saws, and from brakes and rolls to presses and ironworkers, KAAST makes it easy to find the right machine for your application.

We stand behind our machines with quick shipping of spare parts and excellent after-sales service. Need in-person training or installation? No problem! KAAST Machine Tools, Your Production Partner.