Rollomatic maintains its global leadership position in the field of cutting tool production and is proud to announce the launch of an Omron automatically guided vehicle with a robotic handling system and a Kawada humanoid robot. The design of these handling systems is in line with increasing demands in the area of “IIoT” and the “SmartFactory”.

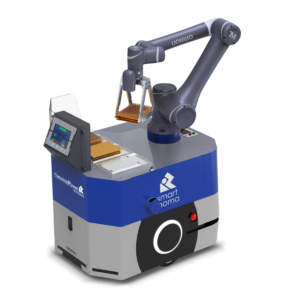

The Omron mobile robot allows the automatic transportation of tool cassettes between different grinding machines and eventual delivery to post‐grinding stations, such as measuring, laser marking, cleaning, packaging, labeling and more.

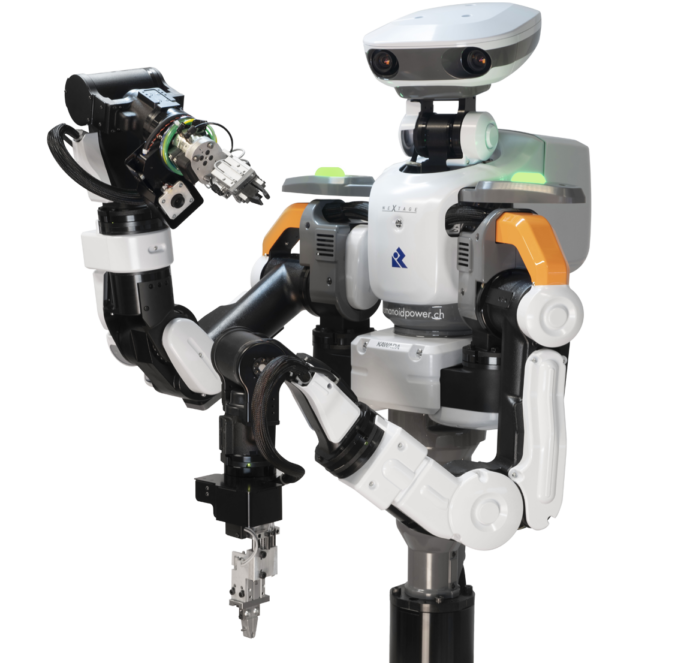

The Kawada humanoid robot autonomously performs tasks such as cassette loading, pre‐grinding or post‐grinding tool inspection, laser marking, placing finished products into packaging tubes and affixing labels to the tubes.

Both the SmartMoma® and the Nextage® robots will be shown in working action during the IMTS 2022 in Chicago. The SmartMoma® will transport full and empty cassettes between the grinding machines and the post‐grinding station. The Nextage® humanoid robot will perform tasks such as tubing and labeling.

Smart Moma® Rollomatic Mobile Handling Solutions by Omron:

- The SmartMoMa® handling system consists of an AGV (automatically guided vehicle) and a highly intelligent 6‐axis robotic arm that integrates specific gripping systems for complex handling.

- This mobile robot is capable of self‐maneuvering autonomously in a production workshop.

- Designed to bring higher autonomy to production machines, it enables loading and unloading of parts without human intervention.

- Additionally, the automation of parts handling between different production operations such as measuring, marking, or packaging can be accomplished.

- The SmartMoMa® mobile handling robot increases the autonomy of production machines while allowing operators to concentrate on tasks requiring more human skills with greater added value.

NEXTAGE® Humanoid Industrial Robot Solutions by Kawada:

NEXTAGE® Humanoid Industrial Robot Solutions by Kawada:

- This is a new type of industrial robot which, given its frame and size, can perform tasks in locations that are difficult for traditional robots to access. It can be installed with ease without the need to redesign production lines.

- This highly efficient humanoid robot can easily be placed where a person usually operates and use its head and two arms, equipped with cameras, to take over any tedious, dangerous or repetitive tasks, allowing workers to focus on areas that require creativity and so generate greater added value.

- Users can control and teach NEXTAGE® what to do with a visual and user‐friendly interface. It can be teamed up with conventional industrial robots or any other specialized equipment and can be considered a true working partner.

- A stand‐alone cassette loading station is available utilizing the Kawada humanoid robot. This is a ready‐to‐go station that loads cutting tool blanks into Rollomatic cassettes from two different types of feeders — o V‐type feeder magazine and Vibratory bowl feeder.

About Rollomatic Inc.

Rollomatic Inc., located in Mundelein, Illinois, is a subsidiary of Rollomatic SA, a privately‐owned Swiss company established since 1989 in Le Landeron, Switzerland. The US Headquarters was launched in 1994 to provide local customer service and support throughout the U.S., Mexico and Canada.

This location features a 29,000 sq. ft. building with a showroom and training area as well as warehouse and engineering offices. Our showroom provides an ideal atmosphere for machine demos, software training and test grinding, while offering an opportunity to explore the latest Rollomatic offerings.

Rollomatic is looking to the future with its partners such as the EPFL (Swiss Technical University in research, teaching and innovation) so it can be right at the center of the innovations and in‐depth discussions shaping the Fourth Industrial Revolution. True to its Swiss origins, the company operates at the highest level of precision and offers 100% Swiss‐built products and services. Rollomatic is in constant pursuit of excellence in quality and accuracy.