Managing the processes of a small manufacturing company is an enormous task rife with challenges to overcome. Here are seven real-life manufacturing challenges that MRP software helps you resolve.

Intro

Manufacturing is hard work. And managing it is even harder. This is especially true for small manufacturers that need to wear multiple hats every single day, making sure that production schedules are accurate and adhered to, that materials reach the shop floor at the right time, that orders are put in and processed in due time, that product quality is up to standard, that costs are kept in check, and so forth.

It’s tough. And it’s made tougher by increasingly heavy regulations, constant supply chain disruptions, and labor capacity fluctuations endemic to our age. But when the going gets tough, the tough get smarter.

A growing number of small manufacturers are turning to software to alleviate their various day-to-day pains. Here are seven real-life manufacturing challenges that genuine companies from various industries have overcome with the help of MRP software.

1. Stockouts and overstocking

One of the biggest issues that MRP software tackles is material planning. The need to find a balance between too little and too much stock is very acute in small manufacturing companies as each unit represents tied-up cash that could be put to good use elsewhere. MRP software is made to accurately determine material requirements, ensure timely stock replenishments, and facilitate demand planning, allowing companies to optimize their inventory.

Paul Long, Website Manager at health and beauty product manufacturer Myddfai Trading Company says: “MRPeasy tells us what our requirements are, and when we create the manufacturing orders, we don’t have to go and tell the manufacturing staff anything, they can simply pull the information from MRPeasy. At the same time, we’re getting flags for stock statuses and can replenish purchases.”

2. Data getting lost

Data is key to making good business decisions. But managing business information in spreadsheets (or even worse, physical archives) is unsustainable in the long run as finding the correct piece of data becomes increasingly difficult as the company grows. Within an MRP system, however, your data is organized in a way that enables easy navigation and quick search.

“We now have all the information in one place – we can see the part, when it’s due, what the costs are, everything. All you need to find is just one click away, which saves us a huge amount of time, and we have eliminated the horrendous paper trail we previously had,” details Lee Brien, Director of Operations at UK precision engineering company A Wrate Engineering.

3. High administrative overhead

3. High administrative overhead

Although necessary, it seems counterproductive to hire additional administrative staff if you could put the same resources into growing the manufacturing side of the business. The level of automation MRP software creates, however, allows companies to significantly reduce administrative tasks, especially those involving data entry and analysis.

Javed Bashir, Production Director at international textile manufacturing company B&A Quilting confirms this: “We are about eight times the size we were in 2017 but have barely doubled the administrative side of things. MRPeasy really has helped us immensely.”

4. Traceability regulations

Being able to track the flow of goods throughout the value chain brings substantial benefits to any company, but especially to those working in heavily regulated industries. Achieving regulatory compliance can be a daunting challenge but it is made effortless by MRP software.

“I had a target to install MRPeasy and become ISO 9001 approved within 6 months. After 6 months of using the system, SGS (an industry-leading certification company) came in to undertake the certification audit and we passed without a single non-conformance. On the report, SGS also commented on how good MRPeasy was with traceability,” states Paul Watson, founder of MPW Precision.

5. Managing complex BOMs

Although the bill of materials functionality is the core of every proper production planning software, many MRP systems do not support complex, multi-level BOMs or BOMs with parameters. Therefore, if you need to manage the manufacturing of intricate products with lots of subassemblies, make sure to find a solution that accommodates that.

Ralph Jones, Director at Britannia 2000 Holdings, knows a thing or two about complex products: “MRPeasy is brilliant, it’s enabled us to build up BOMs for all our products. We have BOMs for each individually printed circuit board and for each sub- and final assembly. It works a treat. One of our mission computers has a BOM of 15-20 pages.”

6. Remote collaboration

For businesses operating from a single facility, the COVID-19 pandemic illustrated the need to be able to work and collaborate remotely. For many companies, however, interregional or international collaboration is an everyday reality regardless of natural disasters or public health crises. In manufacturing companies, this is enabled by using cloud-based MRP software.

“We had staff in two locations in the US, plus the procurement department in Taiwan, therefore we needed a system that could be accessed from anywhere,” says Dennis Lan, Supply Chain Director at lighting systems manufacturer Anthem One. “Before implementing MRPeasy, it was hard to tell which part was where. Now, we know exactly.”

7. Scaling up

Although growth is generally a positive thing, scaling up operations can be very tough for managers. While spreadsheets cannot accommodate a growing business for too long, even some MRP systems can become an impediment if their functionality is not up to par with what serious manufacturers need. That is why considering your future requirements is as important as considering current ones when choosing a software.

Paola Dyboski, founder of Dr Zigs bubble toy company, feels confident about further growth: “There is definitely more functionality to roll out and I am sure we will implement [the MRP system] further as the need arises and our use case and abilities grow. Because MRPeasy grows with you, you can decide as you go, how much you want to implement and then do it in stages.”

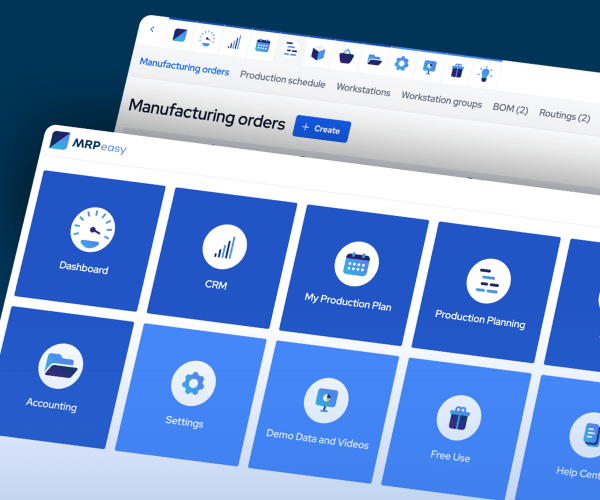

MRPeasy is a manufacturing resource planning software for small manufacturers with up to 200 employees. Integrating sales, production, inventory, purchasing, and finances, the software provides you with an accurate real-time overview of your manufacturing operation. For more information and a free trial, visit https://www.mrpeasy.com/