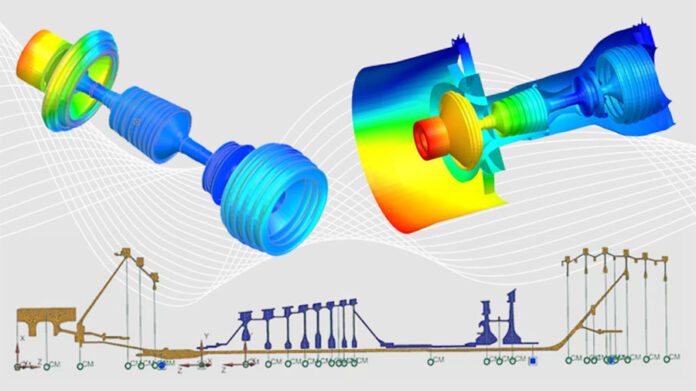

Rotor dynamics analysis software provides a digital model to assess the survivability of the rotating system in a wide range of situations, evaluate complex vibrations and instabilities under real operating loads. Rotor dynamics analysis software from Siemens provides powerful geometry editing functionalities, meshing, and solver technologies combined with user-friendly postprocessing capabilities to perform analyses efficiently.

Rotor dynamics analysis helps engineers to predict and prevent critical operating conditions of rotating machines.

Join this webinar and discover how an integrated multi-physics simulation solution addresses the rotating machinery manufacturer’s engineering challenges accurately and effectively while accelerating product time-to-market.

In this webinar, we demonstrate different types of rotor dynamics analysis in an integrated CAE environment, including:

- Critical Speed assessment

- Response to unbalance and misalignment

- Model reduction to save computation cost

Campbell diagram: compute the critical (or whirling) speed of rotating machines

The critical speed is the speed at which the system can become unstable, engineers must be able to accurately predict those speeds as well as to detect possible resonance problems before real commissioning.

Campbell’s diagram is used to identify critical speeds and shows how the frequencies of the complex modes change with the rotational speed of the rotor.

Perform synchronous and asynchronous rotor dynamic analysis to generate Campbell diagram data, predict whirl frequencies and critical speeds, and detect instability

Rotor stability and imbalance

Rotor instability is a dangerous phenomenon and reliable prediction of rotor stability is a challenging task especially due to the increased complexity of the system and component interdependence. Rotor dynamics analysis helps the engineer to get detailed insight into the origins of imbalance, its cause, and eliminate instability.

Suppressing unnecessary vibration of a finished prototype is often cumbersome and complex. Using a flexible rotor dynamics simulation software engineers can analyze rotor stability, vibration issues, and imbalance issues along the design cycle.

Address torsional vibration challenges of rotating machines

Rotating machines undergo torsional, axial, and lateral vibrations. Engineers need to perform sensitivity analyses i.e., analyze the vibration amplitudes during static and transient excitation of the system. The rotor dynamics simulation software permits users to evaluate the design modification impact on machine vibration before building an expensive physical prototype.

Siemens Digital Factory (DF)

Siemens Digital Factory (DF) offers a comprehensive portfolio of seamlessly integrated hardware, software, and technology-based services in order to support manufacturing companies worldwide in enhancing the flexibility and efficiency of their manufacturing processes and reducing the time to market of their products.

About Siemens USA

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation, and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 379,000 employees in 190 countries, Siemens reported worldwide revenue of $94.0 billion in fiscal 2018. Siemens in the USA reported revenue of $23.7 billion, including $5.0 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.