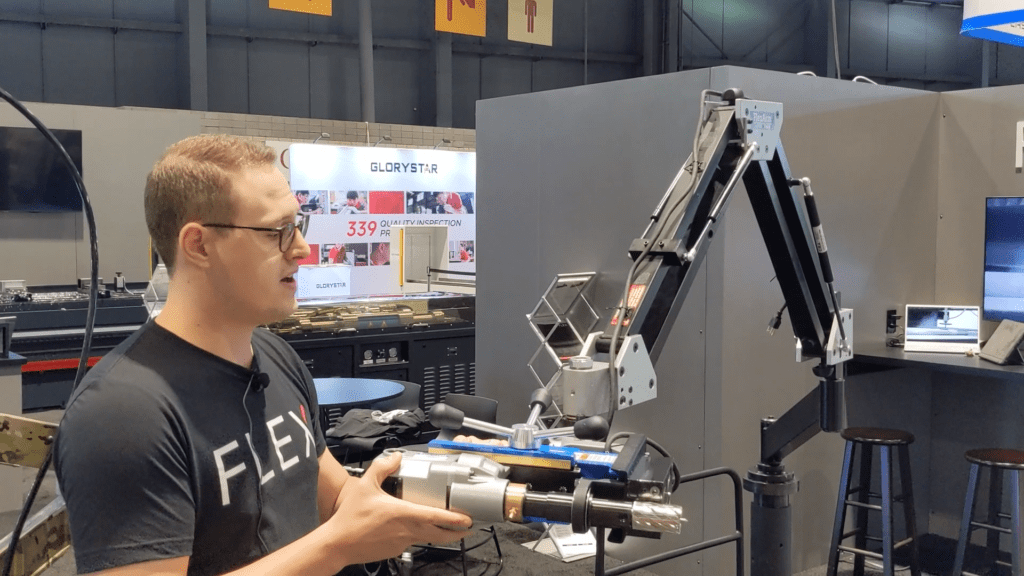

In this edition of Talking Shop, we’re joined by Logan Skelly, the Sales Manager at Flex Machine Tools. Based in Wapakoneta, Ohio, Flex Machine Tools is a trailblazer in the industrial machinery sector. The company is renowned for its innovative and efficient products, including the FlexCNC long bed vertical machining center, FlexJet waterjet cutting solution, FlexArm tapping and die grinding arms, FlexBEAM CNC, and FlexErgo line. These products highlight the company’s commitment to precision, efficiency, and ergonomic solutions, addressing various industrial needs and enhancing productivity.

IMD: We’re thrilled to be here with Flex Machine Tools. Logan, could you tell us more about your latest innovations this year?

Skelly: Absolutely! We’re excited to showcase our latest innovations, including the limited edition A32 FlexArm tapping arm. We’ve given it a unique camo design and are donating 10% of all proceeds from this edition to the Wounded Warriors Project.

IMD: That sounds fantastic. What other products are you highlighting?

Skelly: We’re focusing on ergonomic solutions, such as our custom-designed products that alleviate operational pain points. For instance, we’ve adapted MAG drills to be more user-friendly by mounting them on a FlexArm, significantly easing their use and improving accuracy.

IMD: That’s quite innovative. Any other ergonomic solutions you’re excited about?

Skelly: Definitely. We’ve transformed heavy grinders into more manageable tools. By adding a balance arm, operators can use larger discs without fatigue, enhancing efficiency significantly.

IMD: Material handling is a big challenge in the industry. How is Flex Machine Tools addressing this?

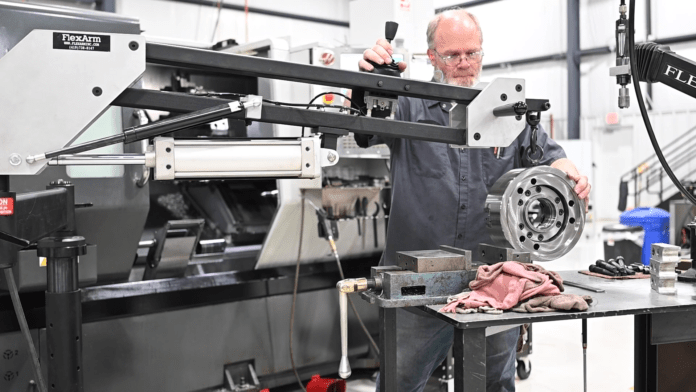

Skelly: We’ve developed a part manipulator arm capable of lifting 250 pounds, mounted on a mobile base for versatility. It’s particularly useful in our own shop for tasks like changing lathe chucks or loading heavy parts onto machine platters.

IMD: The FlexArm tapping arm is a legacy product. Can you elaborate on its benefits?

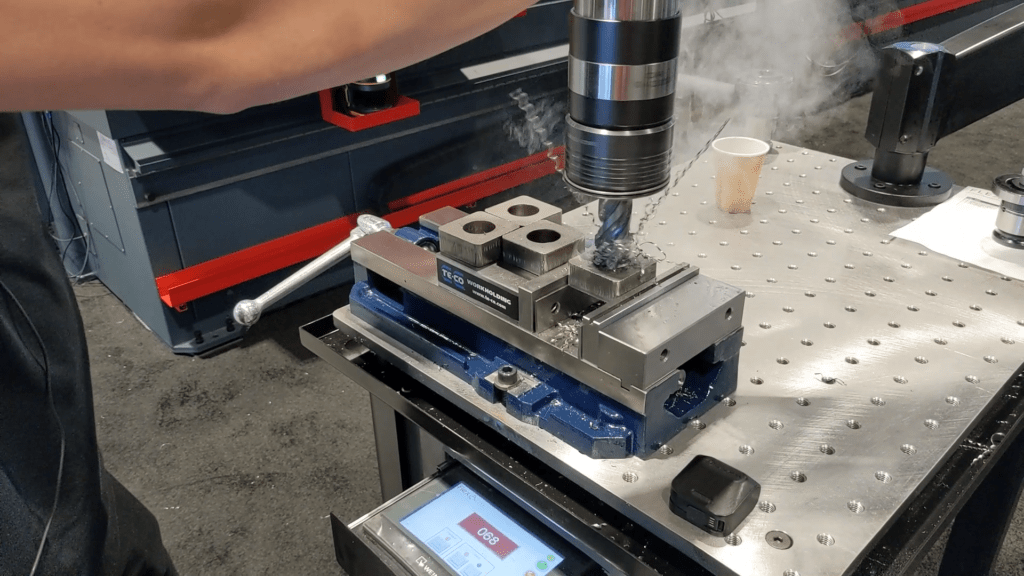

Skelly: The FlexArm tapping arm revolutionizes the tapping process, offering perfect holes every time with minimal effort. It’s especially useful for avoiding tap breakages, with features like automatic depth stop and manual mode for precision.

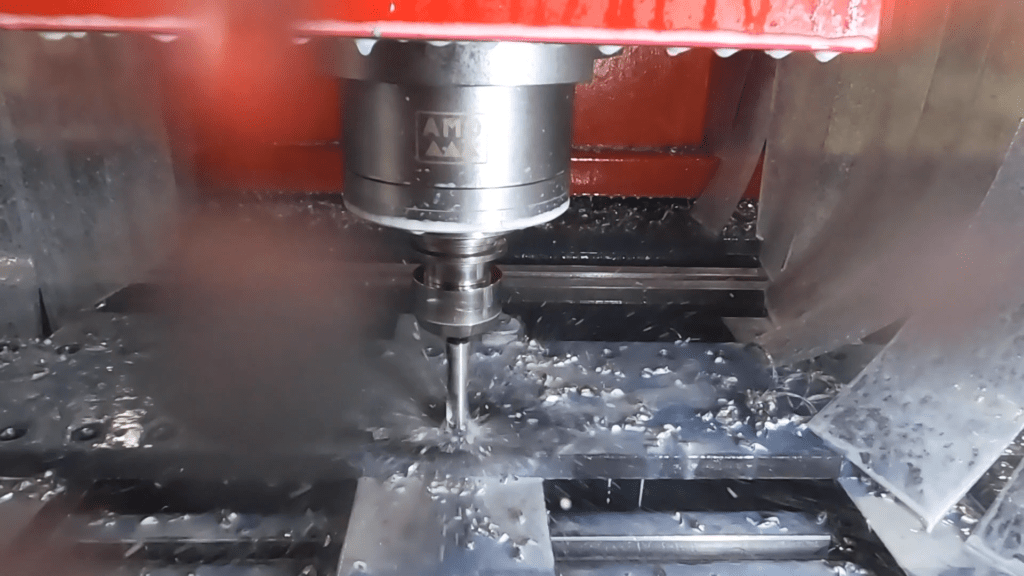

IMD: And the FlexCNC?

Skelly: Our FlexCNC is a game-changer for handling long, large parts. Its open bed design and pendulum mode increase throughput and accuracy, making it a valuable asset in the fabrication industry.

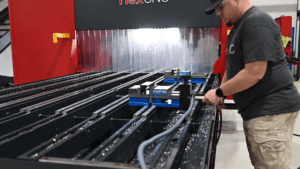

IMD: Tell us more about the FlexJet water jet.

Skelly: The FlexJet is our latest high-performance water jet. It features high rapids, advanced motion control software, and is available in three models. We’re excited about its potential impact on the water jet sector.

Deep Dive into Flex Machine Tools’ Innovative Product Range

FlexCNC Long Bed Vertical Machining Center

The FlexCNC stands out for its ability to handle long, large parts, a common challenge in the fabrication industry. Its unique open bed design and pendulum mode enhance productivity by allowing simultaneous setup and machining operations, leading to higher throughput and accuracy. This machine is a testament to Flex Machine Tools’ commitment to solving complex machining challenges.

FlexJet Waterjet Cutting Solution

Entering the water jet sector with a splash, the FlexJet is a high-performance cutting tool characterized by its high rapids and advanced motion control software. Available in three models, it caters to various cutting needs, ensuring precision and efficiency. Its introduction is a significant move for Flex Machine Tools, showcasing their expansion into diverse machining technologies.

FlexArm Tapping and Die Grinding Arms

The FlexArm series, including the innovative tapping arm, revolutionizes processes like tapping, grinding, and drilling. These arms provide ergonomic solutions, reducing operator fatigue and increasing precision. The tapping arm, particularly, is renowned for its ability to produce perfect tapped holes while minimizing tap breakage, a common issue in manual tapping.

FlexBeam CNC for Structural Machining

The FlexBeam is another example of Flex Machine Tools’ engineering excellence. Designed for structural machining, this CNC machine provides precision and efficiency in processes like drilling, milling, and tapping on large structural components.

FlexErgo Ergonomic Solutions

Flex Machine Tools’ commitment to ergonomic designs is evident in the FlexErgo line. These products, such as the part manipulator arm, are designed to ease the physical strain on operators, improving safety and efficiency in the workplace. Their solutions in handling heavy tools and components demonstrate their understanding of the practical challenges in industrial environments.

Customer Testimonials and Industry Applications

Customer Experiences

Flex Machine Tools has garnered praise from various sectors for their products’ impact on efficiency and ergonomics. Customers from the automotive, aerospace, and manufacturing industries have noted significant improvements in their operations, highlighting the ease of use and precision of Flex Machine Tools’ equipment. These testimonials underscore the real-world benefits of their machinery, from reduced operator fatigue to increased productivity.

Impact on Industry

Flex Machine Tools has been instrumental in transforming traditional manufacturing processes. Their machinery has enabled companies to tackle complex tasks with greater accuracy and less physical strain. Particularly in industries where precision and efficiency are paramount, such as aerospace and automotive manufacturing, Flex Machine Tools’ innovations have been game-changers.

Future Prospects

Looking ahead, Flex Machine Tools continues to innovate, focusing on integrating advanced technologies like AI and automation into their products. Their commitment to ergonomic design and operational efficiency ensures they remain at the forefront of the industrial machinery industry.

Flex Machine Tools stands as a testament to the power of innovation, precision, and ergonomic design in enhancing industrial operations. Their diverse product range, backed by positive customer feedback and significant industry impact, positions them as a leader in the field.

Flex Machine Tools

In an era where efficiency, precision, and worker safety are paramount, Flex Machine Tools emerges as a beacon of innovation and reliability. Their commitment to solving complex industrial challenges through advanced technology and thoughtful design not only sets them apart but also drives the industry forward. As they continue to evolve and expand their product offerings, Flex Machine Tools remains a key player in shaping the future of industrial machinery.