Q: How would you describe your company’s primary business?

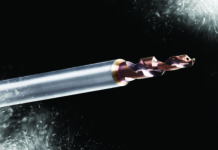

A: Hypneumat provides high speed drilling and tapping units pneumatically, hydraulically or servo driven, as well as multi-spindle drilling and tapping heads. Hypneumat offers an array of custom fixed spindle multi-head configurations, adjustable gear driven heads, universal joint heads and clutch tappers.

Q: In brief, what is the history of your company?

A: In 1942 Earl Putrow, a self-taught inventor living in Northern Wisconsin, was selling motors, belts, pulleys and tooling gadgets through his garage-based company, Putrow Industrial Supply. Earl would display his wares at all key trade shows. At these shows, he would bring along a showpiece item he dubbed “The Hypneumat”.

The Hypneumat was cleverly coined from three existing words: hydraulic, pneumatic and automatic. Putrow’s Hypneumat was the first high-speed automatic drilling and tapping unit. Since that time, Hypneumat, Inc. has developed into the leading supplier of automatic drilling and tapping units, which customers find in nearly every major manufacturing industry throughout the world.

Q: How has your company changed through the years?

A: Hypneumat has had to adapt to the evolution of CNC machining centers eating into the dedicated machinery market, over the past 25 years. This was accomplished by creatively designing automation solutions that can handle high volume requirements with a flexibility that provides additional options for the end user. The last three to five years has seen a resurgence in dedicated drilling and tapping needs, and Hypneumat has positioned itself for those opportunities.

Q: What have been some interesting applications of your products?

A: Hypneumat designed and built a machine with a DQ56E series feed unit powered by a high efficiency on demand hydraulic power package and 7.5HP spindle motor. This drilling unit drives a custom 20 spindle adjustable heavy-duty multi-head, drilling twenty (20) 1-1/4” holes in high-density polyethylene inlet tubes.

Other Interesting applications include: Drilling bung holes for wine and whiskey barrels, spin pizza crusts, form pie crusts, drilling holes in large irrigation pipe, tapping mount holes for appliance units, tapping fasteners for the aerospace industry and providing drilling systems for the semi-trailer industry.

Q: How has been an asset to the success of Hypneumat?

A: Hypneumat, Inc. continues to innovate and position itself to meet the many needs of its customers. The company prides themselves on the well-trained craftsmen and journeymen machinists who work at Hypneumat. Personal pride and integrity are part of every operation, from order taking to shipping.