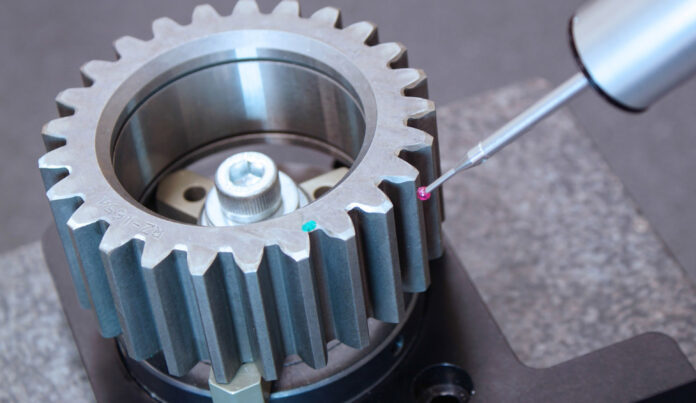

Coordinate measuring machine (CMM) manufacturer LK Metrology has introduced a third release of its CAMIO 2021 programming and measurement software featuring numerous improvements. The most significant is the inclusion of a module that automates the inspection of spur and helical involute gears.

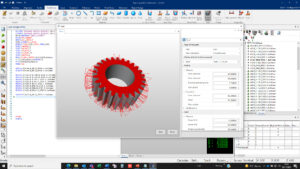

CAMIO GEARS makes it possible to begin measuring the specific geometry of gears quickly by using the core capabilities of CAMIO software to generate straightforward inspection programs, advanced gear reports and automated probe calibration routines.

For each gear type, the software has a unique set of definitions, evaluation algorithms and reporting graphics conveniently packaged in one add-on module, making it easy for users to bring a new capability to their existing CMM. The module supports alignment of the gear axis during measurement using any of the three CMM axes and traditional touch trigger probes or advanced scanning probes.

Several other improvements have been incorporated into CAMIO 2021 R3, the availability of which was announced at the end of November. Smart 3-2-1 datum alignment is new functionality that intelligently selects the datum axis and origin constraints, as well as the most suitable datum features using best-practice techniques. Should the user change the alignment properties manually, the selections automatically update.

Explorer Tree Datum Definition allows datum features to be defined more efficiently directly from the feature explorer, with the option of specifying the datum label. Report Table Feature Order provides new options for controlling the order in which features are reported in graphical tables, either alphabetically, by program output or in a user-defined order.

Teach-path coordinates and directions may now be defined using the CAD model. The GD&T (geometric dimensioning and tolerancing) reporting algorithm has been further enhanced to be independent of the standard used. Finally, there is new capability for retrieving points from a feature measured using a tactile probe, complementing existing functionality for retrieving data from a point cloud.

For CAD users, exchange file versions are compatible with the latest release of Spatial’s InterOp, as was the case in the previous iteration of CAMIO 2021. The interoperability software is an industry-leader in CAD data translation that enables users to import, interact with, share and export 3D data easily across CMM platforms and manufacturing sites.

For CAD users, exchange file versions are compatible with the latest release of Spatial’s InterOp, as was the case in the previous iteration of CAMIO 2021. The interoperability software is an industry-leader in CAD data translation that enables users to import, interact with, share and export 3D data easily across CMM platforms and manufacturing sites.

CAMIO 2021 R3 encourages novice as well as experienced users to drive the inspection process graphically from the CAD model, either online or offline, although teach-and-learn using the CMM handbox is available. An advanced user interface makes part alignment, feature inspection and dimensional tolerancing fast and intuitive.

The virtual CMM programming environment means that accurate axis movement and probe motion sequences may be simulated for collision detection and cycle time estimations. Help Files now use a version of HTML5 help that supports modern internet browsers, such as Microsoft Edge and Google Chrome, and link to locally installed help pages.

CAMIO 2021 supports Metrology Gate, Industry 4.0 software that enables production teams to view and analyse quality data and monitor all CMM activity remotely from any internet-connected device. The web-based portal provides 24/7 access to information from any enabled metrology device for automatically retrieving inspection results and a summary of errors, a record of program changes, uptime of the CMMs and OEE (overall equipment effectiveness).

Historical logs assist troubleshooting and warn when routine maintenance is due, not only of the inspection machines but also of the machine tools or other equipment on which the components are being made. The software provides a modular solution for various levels of CMM automation to raise productivity, cost effectiveness and product quality.

About LK Metrology

LK Metrology is renowned for innovative metrology solutions and services. The company’s products, including coordinate measuring machines (CMM), portable measuring arms and metrology software, are used worldwide to control and improve the quality of manufactured components. Its precision technology underpins the process chain from design, development, production and assembly through to quality assurance in global industries such as automotive, aerospace, defence, motorsport, energy, medical and contract inspection.

Established in England in 1963, LK Metrology has an impressive heritage in metrology dating back to the birth of CMM technology. Founded by CMM pioneer Norman Key and his father-in-law Jim Lowther, LK Metrology is credited with many of the CMM industry’s firsts including the first bridge-type design, first OEM to integrate computers, first to use a touch trigger probe, first to develop inspection software, first to use all air bearings and granite guideways, first to use carbon fibre composite spindles, first to use microprocessor-controlled drive systems, first to produce a truly thermally stable CMM and first to produce a high-accuracy horizontal-spindle CMM.

In 2018, LK Metrology was relaunched as an independent CMM manufacturer after several years as a division of Nikon Metrology. Headquartered in the UK, LK’s CMM development and production are at the company’s facility in Castle Donington. Sales and support offices are in the UK, North America, Belgium, France, Germany, Italy and China, supplemented by a worldwide distributor network.