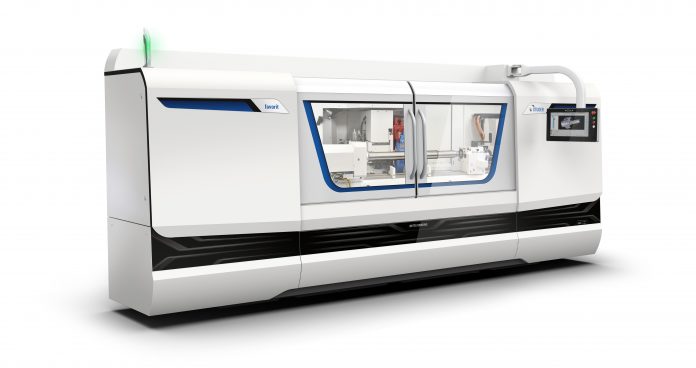

IMTS 2018 visitors to UNITED GRINDING in booth 236802 will have an in-person opportunity to experience the new STUDER favorit 1600 with a distance between centers of 1600 mm. The new STUDER favorit 1600 grinds both single-part and batch production, combining cost-effective price with high productivity. With a center distance of 63″ and a 6.89″ center height, the universal machine handles long workpieces weighing up to 330 lbs.

The STUDER favorit incorporates a full enclosure with an optimal view of the grinding process. A solid Granitan® base anchors the machine for maximum precision, performance and stability. The machine’s wheelhead, which can be positioned in 3° increments, houses a belt-driven external and internal grinding spindles.

STUDER’s grinding software with StuderPictogramming enables even less-experienced users to program grinding and dressing cycles quickly and efficiently. Optional StuderGRIND software handles special applications such as profiling the grinding wheel for complex workpiece shapes.

Process-oriented development, production, assembly and testing of STUDER products comply with the strict guidelines of VDA 6.4 and ISO 9001.

About United Grinding North America, Inc.

United Grinding North America Inc., a subsidiary of the UNITED GRINDING Group, represents a union of some of the strongest companies in grinding and ultra-precision finishing solutions for the manufacturing industry. Through its surface and profile grinding, cylindrical grinding and tool grinding technology groups, the company sells and supports precision machines for grinding, eroding, laser ablation, combination machining and measuring under the MÄGERLE, BLOHM, JUNG, STUDER, SCHAUDT, MIKROSA, WALTER and EWAG brands. Headquartered in Miamisburg, Ohio, UNITED GRINDING North America is ISO 9001 certified to ensure quality in product development, production, shipping and support operations.