TRUMPF is launching its TruMatic 5000 manufacturing cell with the new SheetMaster to the North American market. Users of the new system will benefit from fully automated laser cutting, punching and forming capabilities. The new SheetMaster enables a fully automated flow of materials within the manufacturing cell – from loading and unloading the machine to removing finished parts.

“The TruMatic 5000 is yet another example of TRUMPF’s market-leading position in the field of connected manufacturing,” says TRUMPF Inc. Product Manager for TruPunch and TruMatic Roger Michaud. “This solution is designed for seamless integration in a self-contained smart factory and will give users efficiency gains along the entire process chain.”

TRUMPF’s new combination machine is equipped with a 6kW fiber laser to maximize productivity. As well as saving energy, this laser does an impressively fast job of cutting sheet metal parts. The system comes with a descending die that prevents parts from being scratched during the punching process. The TruMatic 5000 punching head also comes with a patented TRUMPF electric drive known as the Delta Drive, which uses around 30 percent less energy.

SheetMaster enables fully automated material flow

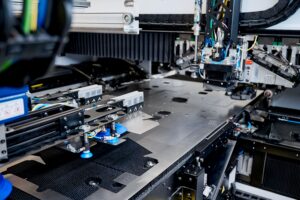

TRUMPF has fully automated the material flow in the TruMatic 5000. This improvement was made possible by the new SheetMaster technology, which uses grippers to handle parts in

the manufacturing cell. The suction cups on the new SheetMaster’s grippers are monitored by sensors and can be activated individually. This makes gripper operation even more flexible, speeding up workpiece handling and saving valuable time, especially for smaller batches. In addition, the SheetMaster can be connected to an automated STOPA storage system which automatically supplies the manufacturing cell with raw material. The system also palletizes and sorts the parts without human intervention. Further benefits of the new SheetMaster include its ability to eject cut and punched parts from the manufacturing cell. Parts can then be transported directly to the next stage of the process. This reduces non-productive time and increases efficiency on the shop floor.

Maximum productivity for small batch sizes

The TruMatic 5000’s automation technology also includes the ToolMaster, a tool changer with up to 90 different tool cartridges that can automatically switch between multiple punching and forming tools. The ToolMaster enables users to produce small, high-mix batches of parts without having to manually retool the machine. Also coming soon, is an automatic nozzle changer with a nozzle inspection function. This prevents unscheduled stoppages during the night, for example due to a damaged nozzle.

“The new TruMatic 5000 manufacturing cell with the SheetMaster is designed for businesses that want to take their productivity to the next level through automation,” adds Michaud. “This punch-laser machine and automation combination is a great option for fabricators looking to improve connectivity and increase productivity without adding headcount.”

TRUMPF’s TruMatic 5000 is suitable for companies that have already introduced connectivity to their shop floor, as well as those that are currently planning to do so. Typical areas of application include production for industrial kitchens, control-cabinet manufacturing, and the furniture industry. The combination machine will be available for delivery in North America beginning in spring of 2025.

About TRUMPF

TRUMPF is a high-tech company offering manufacturing solutions in the fields of machine tools and laser technology. It drives digital connectivity in manufacturing through consulting, platform products, and software. TRUMPF is one of the technology and market leaders in highly versatile machine tools for sheet metal processing, and in the field of industrial lasers. In 2023/24, TRUMPF employed approximately 18,550 people and generated sales of around 5.2 billion euros (preliminary figures). With about 90 companies, the TRUMPF Group is represented in Europe, North America, South America and Asia. The company has production facilities in Germany, France, the United Kingdom, Italy, Austria, Switzerland, Poland, China, the Czech Republic, the United States and Mexico.