KHS Group has now launched a filling and packaging system for PET bottles to market which incorporates a stretch blow molder, labeler and filler. With consistent neck handling KHS also enables lightweight PET to be processed. This means that a 0.5-liter bottle weighing notably less than eight grams can now be produced, for instance.

“For years we’ve been seeing an increasing move towards blocking – although in some applications single machine systems definitely still have profound advantages. At the same time we’re constantly researching further innovations,” explains Frank Haesendonckx, head of Sales and Technology at the KHS factory in Hamburg, Germany.

“For years we’ve been seeing an increasing move towards blocking – although in some applications single machine systems definitely still have profound advantages. At the same time we’re constantly researching further innovations,” explains Frank Haesendonckx, head of Sales and Technology at the KHS factory in Hamburg, Germany.

This trend does not surprise him as conventional air conveying segments especially are relatively prone to error. There is also the fact that space has become a critical factor for many companies over the past few years and that a general drift towards more compact lines is being noticed. The KHS block also has many advantages: bottle handling is easier, efficiency and hygiene are considerably increased and there is no longer any need for air conveying segments. The option of also integrating a labeler into the block is new, meaning that containers are fully conveyed within one machine from bottle manufacture to labeling. This not only saves space but also energy and manpower costs as the system can be operated by one person thanks to the very few conveying segments between the individual machines.

“More and more customers thus want more compact lines,” says Haesendonckx. He explains that the KHS InnoPET TriBlock evolved within an incredibly short space of time.

“We obtained convincing results very quickly during development as we were able to base the new system on our own tried-and-tested technology.” The outstanding cooperation between the various German production sites, namely filling technology in Bad Kreuznach, labeling in Dortmund and stretch blow molding technology in Hamburg, greatly contributed to the success of the development.

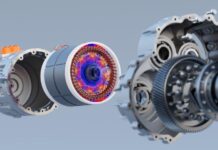

The result of this process, the KHS InnoPET TriBlock, comprises the energy-efficient KHS InnoPET BloFill stretch blow molder/filler block plus an additional labeling function. Both still water and carbonated beverages can be bottled on this compact blocked system in the minimum amount of space. The high-performance machines have a maximum output of 81,000 PET bottles per hour. Haesendonckx is also proud of the machinery’s special preglued technology which could be integrated into the TriBlock with the help of an Italian design partner.

This ensures that the PET bottles are not exposed to any hot melt vapors throughout the entire process. The labels are applied to the PET bottles using what is known as Adhesleve technology, where the preglued labels are fed to a vacuum drum, cut and applied to the bottle using the same drum. They then stick to the bottle automatically. With this unique no bottle, no label principle the KHS TriBlock ensures a high level of efficiency as no label is applied where no bottle passes the labeling drum. In this way the machine not only prevents label waste but also hinders any disruptions in the flow.

As opposed to conventional systems beverage producers can also process lightweight PET bottles on the new system, allowing operators to manufacture 0.5-liter bottles weighing much less than eight grams, for example. This is made possible by the fact that the system uses consistent neck handling throughout; whether they are being gripped, stabilized or turned, the bottles are fed through the individual work steps by their necks only. “This means that the sensitive lightweight bottles are no longer subjected to any unnecessary stress,” states Haesendonckx. “With this system beverage producers can save up to 1.5 grams in weight per PET bottle compared to the standard systems in use to date.”

Haesendonckx is also very optimistic about the future. “The KHS InnoPET TriBlock perfectly fits in with the KHS blocking concept.” With this he means a base system for synchronizing a number of different systems, with which various single machines can be blocked within a standardized module. “The TriBlock we’ve now come up with is thus far from being the last of our ideas. Its fast development just goes to show that we’re able to react quickly to customer requirements at any time,” Haesendonckx smiles. In the future KHS will continue to add to its existing range of blocked systems, thus extending its product portfolio.

For more information go to: www.khs.com