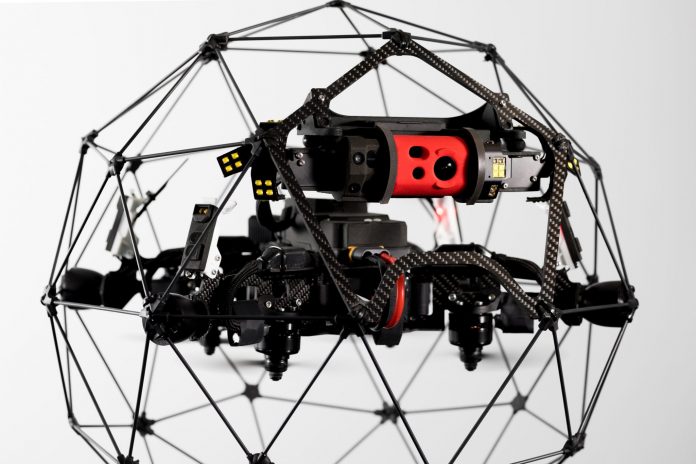

The use of drones for asset inspection is fast becoming a preferred method within the oil and gas industry, as well as for chemical companies. Such visual surveillance offers a multitude of advantages, including those of safety, significantly lowered costs, improved data collection and reduced asset downtime. With over 200 deaths and 15,000 serious injuries each year in confined spaces*, companies are reaping the benefits of utilising robots, drones and Unmanned Aerial Systems that remove the need for humans to enter hazardous areas and spaces.

Challenges of traditional asset inspection

There are multiple challenges when it comes to traditional methods of asset inspection. The most pressing is that of human safety. This includes:

- The need for humans to enter confined spaces with limited exit points

- Working at height

- Areas that contain materials or an atmosphere hazardous to human life

- A lack of oxygen within a confined space

- Dangers involved with evacuation and rescues following an incident

Another issue is that of cost. Carrying out asset inspection in the traditional manner takes up a large proportion of company budget in a varying number of ways:

- Asset shutdown

- Site shutdowns

- Outage periods

- Erection of any necessary scaffolding

- Risk assessments

- Any necessary HSE implementation

- Increased insurance costs

In addition, traditional asset inspection is time consuming, both in the planning and the application. There is also a further issue when it comes to the quality and accuracy of data collection and the need to factor in human error.

Advantages of using drones for asset inspection

Using drones for asset inspection has many advantages.

- Minimising risk and danger:

Using drones creates a dramatic increase in worker safety. This is highlighted ever further in the case of facilities such as oil and gas refineries that have multiple hostile environments including confined spaces, tall and complex stacks and pipelines, hazardous materials and areas with oxygen-poor atmospheres. Minimising the amount of human intervention needed for such asset inspection drastically reduces the chance of worker injuries or fatalities. - Speed of deployment and inspection:

The use of drones for asset inspection can be deployed within a very short time scale. Because of this they are suitable for both regular and emergency scenarios, and can carry out an inspection far quicker than that done by humans. Such surveillance carried out by drone is typically reduced from days to mere hours. - Higher quality data:

Drones can navigate at close quarters to structures, meaning they can capture images and video in great detail. They can also carry this out from angles that humans cannot, thus providing superior inspection abilities and removing the aspect of human error. This data is easily shareable using standard software and analytical tools. - Minimises downtime:

With less need to erect scaffolding, towers and other equipment, surveillance can be carried out faster. This means less downtime and more productivity. - Lowered insurance costs:

Removing the necessity of manual inspection reduces insurance costs for both inspectors and workers. It also removes the need for costly HSE procedures. - High flexibility:

Drone inspection can be utilised in many industry scenarios, both indoors and outdoors, at height, in confined spaces and more.

Another major advantage of the highly reduced costs of drone asset inspection is that it provides an incentive to take proactive action with preventative inspections, rather than doing this only when required by regulations or when absolutely necessary. Such action has many positive repercussions, including increased efficiency, less downtime for unscheduled maintenance and repairs and increased worker safety.

About Nexxis

Perth-based company, Nexxis, are providers of drone technology to industries across Australia. With a team dedicated to understanding an organisation’s individual needs they work with companies to determine how this fast evolving resource can overcome the many challenges of traditional asset inspection.

P: 08 9418 4952

* Click HERE for 2016 OSHA figures