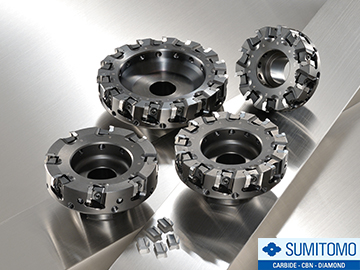

SUMITOMO DEVELOPS HF PCD MILLING CUTTER FOR HIGH EFFICIENCY ALUMINUM CUTTING

Sumitomo Electric Carbide, Inc.’s new HF PCD Milling Cutter provides highly efficient cutting of aluminum and non-ferrous materials. For exceptional milling efficiency, the HF Series features a high-density design (3 teeth per inch).

In addition to productivity, the HF Series Milling Cutter is engineered for precision. The unique double-chamfered cutting edge of the insert eliminates burrs and ensures superior surface finishes. The HF Series achieves a run-out precision of 5µm (0.0002”) or less. In addition, the shape and structure of the wedge clamp’s locating mechanism prevents dislocation from centrifugal force and ensures safety and ease of use.

For reduced running costs, the HF Series offers a drastic increase in the amount of insert regrind (to 0.07”) compared to conventional screw lock types.

The HF Series employs an air/coolant through system for improved chip evacuation and a longer tool life.

About Sumitomo

For a quarter century, we’ve made it our mission to design and produce exceptionally innovative and advanced cutting tool solutions. Our aggressive R&D and design ingenuity give you more choices in turning systems, drilling systems, milling systems and inserts, including PCBN and PCD coated versions. Every Sumitomo solution is painstakingly developed to meet your need for higher productivity and precision.

The Sumitomo business was started in Kyoto, the historic capital city of Japan, nearly 400 years ago by Masatomo Sumitomo (1585-1652) and Riemon Soga (1572-1636).

Masatomo is regarded as the spiritual founder of the Sumitomo Group. Following an early career in the Buddhist priesthood, he established a shop in Kyoto that sold medicines and books. In accordance with the custom of his time, Masatomo produced written teachings for his household and disciples. One volume of these, which provided advice on the conduct of commercial activity, has come to be known as the “Founder’s Precepts” and is the basis of code of conduct, still today, for the Sumitomo Group of companies.

Riemon, who was a disciple and brother-in-law of Masamoto, was the technological pioneer who set the Sumitomo business on the path to commercial success. Having studied copper refining, Riemon established the Izumia copper business in Kyoto in 1590. Until the late 16th century, Japanese copper merchants did not possess the technology to extract the silver contained in copper ore, which compelled them to export the ore with the silver intact. By learning and perfecting Western smelting methods, Riemon engineered a revolution in Japanese copper refining. The Sumitomo business was continued by Riemon’s eldest son, Tomomochi (1607-1662), who entered the Sumitomo family through his marriage to Masatomo’s daughter. Tomomochi moved the copper smelting business to Osaka, Japan’s commercial capital at the time.

One of the epoch making events in the early days of the Sumitomo family was the 1690 opening of the Besshi Copper Mine on the island of Shikoku, across the Seto Inland Sea from Osaka. The Besshi Copper Mine was extremely productive and profitable, right up to the early 20th century. Consequently, it played a pivotal role in the birth of many core companies of the Sumitomo Group today. In 1891, Sumitomo formulated its Business Principles, which are based upon the “Founder’s Precept” by Masatomo.

For more information, visit IMTS Booth #W-2422 or contact Sumitomo Electric Carbide, Inc., at www.sumicarbide.com.