Following its successful launch, SUHNER is presenting the BEA 16 spindle machining unit with an all new drive and control concept. The objective of this new development was the integration of the latest servo drive and control technology from Bosch Rexroth. Software developed additionally allows the user to program six different basic cycles without prior knowledge of CNC.

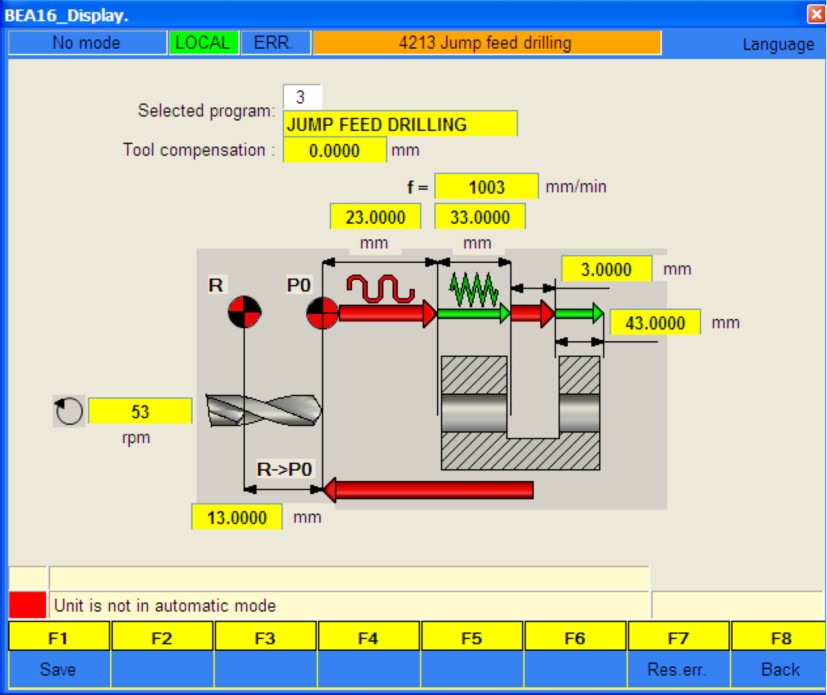

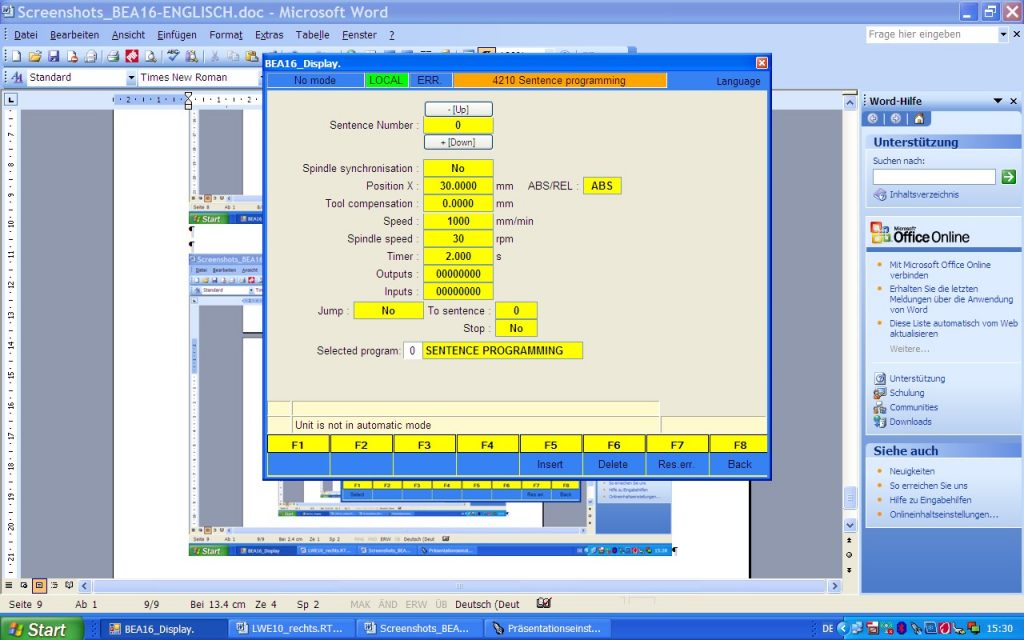

By visualizing these six cycles – drilling – combined drilling (drilling and thread cutting with the one tool) – thread cutting – drilling with chip removal – drilling with jump function – undercutting, the unit has become extremely easy to program.

The BEA 16 machining unit itself is a precision device from the SUHNER spindle machining unit series that has been designed for gruelling continuous use in multiple shift operations. The BEA 16 has a drilling capacity of 16 mmØ in 450 N/mm2 steel. The max feed path is 140 mm, and the max speed is 500 rpm.

Today, rising production piece numbers and greater workpiece complexity with all-round machining are leading to a renaissance of the so-called special machine. However, today’s special machines are being used no longer as purely single-purpose solutions, but rather for whole part families.

These require different machining cycles, feed speeds, feed paths and rotating speeds, and, of course, must allow fast retooling. And it is these requirements exactly that the BEA 16 will meet to the full.