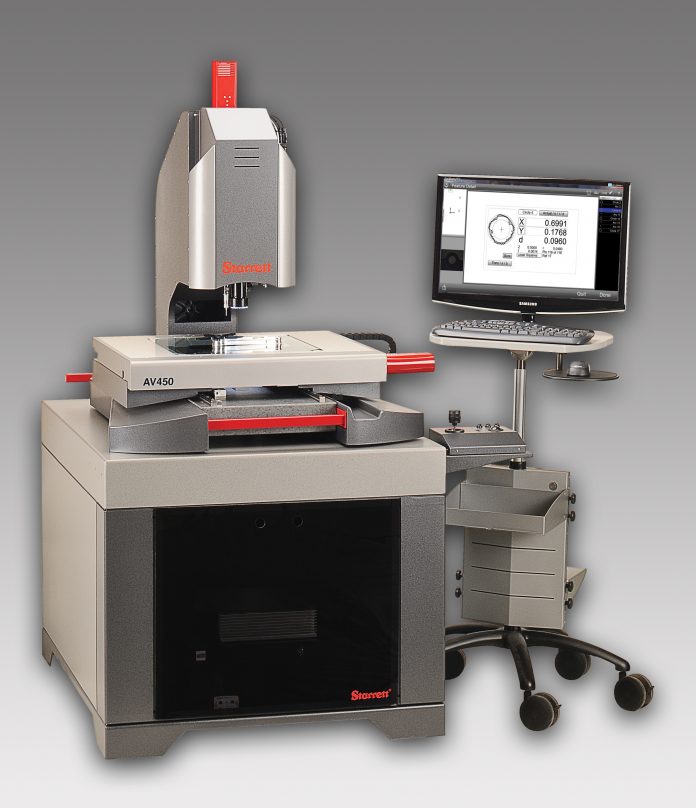

The L.S. Starrett Company, a leading global manufacturer of precision measuring tools and gages, metrology systems and more, has introduced its AV450 Automatic Vision System. Versatile, accurate, fast, and American made, the new 3-axis vision system allows users to cost-effectively achieve high throughput in their inspection process, and is ideal for both repetitive, larger part-run applications and routine quality assurance.

Featuring a larger X,Y,Z measuring envelope of 18″ x 14″ x 8″ (457 mm x 356 mm x 203 mm), the Starrett AV450 has high-resolution video zoom optics and it can be pre-programmed (CNC) for repetitive part inspection, or driven manually via a trackball for individual measurements. With its highly stable mechanical design, precision linear bearings, and smooth stage motion, maximum performance and throughput is easily attainable. Throughput is further enhanced by either QC5000 or MetLogix™ M3 software that controls video edge detection and multiple-channel fiber optic or LED illumination. Computer-controlled Quadrant (LED) ring lighting, sub-stage lighting, and optional through-the-lens lighting meets the most challenging illumination requirements.

Accuracy of the Starrett AV450 Automatic Vision System is 2.5 + 5L/1000 and reading resolution is 4 µin (0.1µm). Magnification on a 24” monitor, 1:1 pixel setting is 37x to 240x 6.5:1 zoom and 25x to 300x with a 12:1 zoom. The system has a 1.3 mega-pixel color digital video camera and a precision granite base.

The AV450 has an external motion control unit and includes a Windows®-based operating system with an operator interface via a desktop PC with a 24” touchscreen monitor, as well as Wi-Fi network connectivity. CAD files can be imported/ exported and reports can be generated and archived. M3 metrology software supports 3-axis measurements and 2D geometric constructs (such as points, lines, angles, rectangles and slots) and corrections for level, skew and datum origin. Touch-screen functionality with a pinch, swipe and touch provides intuitive operation for all users.

Options for the AV450 include a Renishaw touch probe kit, Optimet laser probe, 0.5x, 1.5x and 2.0x auxiliary lenses, an LED dark-field quadrant illuminator and a DXF/ field-of-view option for automatic comparison to CAD files. Other options include a CNC rotary axis fixture, touch probe change rack, calibration standards, part fixtures and workholding devices.

Click HERE for more information on the Automatic Vision System

About The L.S. Starrett Company

Founded in 1880 and headquartered in Athol, MA U.S.A., The L.S. Starrett Company is a leading global manufacturer of precision measuring tools and gages, optical comparators and vision systems and force and hardness testing solutions. Starrett also manufactures laser measurement systems, custom engineered granite solutions, custom gaging, band saw blades, power tool accessory saw blades, workshop tools and jobsite tools. The Starrett brand is recognized throughout the world for exceptional quality and precision. Skilled personnel, superior products, manufacturing expertise, innovation and excellent service and support have earned Starrett its reputation as the “World’s Greatest Toolmakers”. Starrett has over 1,600 employees worldwide and annual sales exceeding $200 million. The company has six manufacturing locations in the U.S.A., including facilities in Massachusetts, North Carolina, Georgia, Ohio, Minnesota and California. Starrett also has three international manufacturing facilities. Plants are located in Brazil, Scotland and China, in addition to distribution centers and offices located worldwide. The L.S. Starrett Company is publicly traded on the NYSE, symbol SCX.