Robot Press Automation for the General Industry

Since the early 90’s industrial robots have commonly been used in the automotive press- shops. It is common using big industrial robot transferring big metal panels between 2000 to 3500 Tn presses. Since robotic automation is becoming more affordable and easier to program robots are increasing its presence in the stamping industry out of the automotive press-shops.

In the traditional press-shops robots are used for press-to- press part transfer as well as for blank de-stacker operations and end of line racking. However more recently robots are more and more applied to smaller press applications out of the automotive industry. Smaller industrial robots are used for the loading and unloading of metal sheets for white goods (ovens, cook-tops, fridges, dish-washer machines…), electronics industry (smart phones, Tv’s, router’s, PC’s…) and other general metal industries.

More than 16.000 small and medium size presses are manufactured every year globally. The total installed base is estimated in some 125.000 presses.

As robotic automation is becoming more affordable and easier to program a greater number of small stamping manufacturers will be able to deploy and integrate them into industrial supply chains. Robotic press loading and unloading is a good alternative to the manual operation. A robot can load and unload a press faster, tirelessly and more safely than a human operator.

To the traditional robot arguments to use robots such as flexibility, improved health and safety and product output today we can add ease-of- use, reduced set-up time and reduced total cost of ownership (TCO).

Moving from Manual to Automatic Production has Never Been so Easy

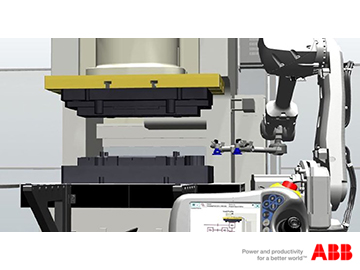

The StampPack® is the ABB solution for the automation of small and medium size stamping presses in record time. It is composed by an ABB robot and a software package, so-called StampApp®.

The standardized power and signal interface creates an easy connection of the robot to the press and to the cell devices (conveyors, de-stacking tables and centering stations). The StampApp® software provides a graphical user interface and a programming wizard running on the robot FlexPendant that helps the operator to easily operate and program without the need to master the robot programming language. The underlying robot program incorporates the experience and feedback gathered after programming more than 2,000 press robots.

The StampPack® is flexible and scalable to multiple configurations. From loading and unloading one single press to a complete stamping process involving several presses and devices (up to 6 cell elements including presses and devices). An off-line computer-based software allows to create the user interface from pre-defined models.

About ABB

ABB is a leader in power and automation technologies that enable utility and industry customers to improve their performance while lowering environmental impact. The ABB Group of companies operates in around 100 countries and employs about 150,000 people.

For more information, visit www.abb.com.

About ABB Robotics

ABB Robotics is a leading supplier of industrial robots – also providing robot software, peripheral equipment, modular manufacturing cells and service for tasks such as welding, handling, assembly, painting and finishing, picking, packing, palletizing and machine tending. Key markets include automotive, plastics, metal fabrication, foundry, electronics, machine tools, pharmaceutical and food and beverage industries. A strong solutions focus helps manufacturers improve productivity, product quality and worker safety. ABB has installed more than 200,000 robots worldwide.

For more information, visit www.abb.com/robotics.