Scalable automation and drive technology package for tapping centers

- Package for tapping centers consisting of compact CNC, frequency converter with triple overload capability and high-speed electric motor

- For ultra-fast tool changes: spindle start-up from 0 to 24,000 revolutions/minute in less than one second

- Scalable functions and performance thanks to control hardware variants

- High speed for high-speed cutting with small tools

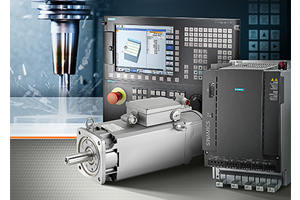

Siemens has put together a scalable package of coordinated automation and drive components specifically for tapping centers. It consists of the Sinumerik 828D compact CNC with new panel processing units PPU2xx.3 of various performance classes as control hardware and the new variant of the Sinamics S120 Combi drive with triple overload capability. The package is completed with the new Simotics M-1PH8 Premium Performance main motor, which can achieve high speeds.

Siemens has put together a scalable package of coordinated automation and drive components specifically for tapping centers. It consists of the Sinumerik 828D compact CNC with new panel processing units PPU2xx.3 of various performance classes as control hardware and the new variant of the Sinamics S120 Combi drive with triple overload capability. The package is completed with the new Simotics M-1PH8 Premium Performance main motor, which can achieve high speeds.

The productivity of tapping centers can be increased considerably due to the specially coordinated components, the powerful control system hardware, the converter with enhanced overload resilience and the high-speed main motor from Siemens.

For example, the spindle can be started up from 0 to 24,000 revolutions per minute in less than one second. This saves considerable time, particularly with tapping center applications featuring frequent tool changes.

The Siemens range is also especially suitable for the increasing number of applications with freeform surfaces and high surface quality, for example cell phone components, which are manufactured with small high-speed cutting (HSC) tools and have short machining times. The tapping center’s maximum machine dynamics can be utilized to the fullest extent with the scalable performance spectrum, for example the different control hardware variants PPU 260.3 or 280.3 for the Sinumerik 828D compact CNC.

Background information:

Tapping centers are designed as machine tools with small work spaces for milling, drilling and thread machining, and are frequently used to manufacture hard disk and mobile phone housings, for example. These are made out of lightweight materials using small tools and at high speeds.

For more information, please visit:

usa.siemens.com/cnc

Or contact:

SiemensMTBUMarCom.industry@siemens.com

The Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly automation and drive technology, industrial software and technology-based services. The Sector’s comprehensive portfolio covers the entire industrial value chain, from product design, engineering and production to services. Siemens enhances its customers’ productivity, efficiency, and flexibility in a wide variety of different industries. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Divisions Industry Automation, Drive Technologies and Customer Services as well as the Business Unit Metals Technologies.