Greener, faster and more productive operations – those are just some of the customer benefits of a revolutionary new approach to machining that is set to change the face of manufacturing.

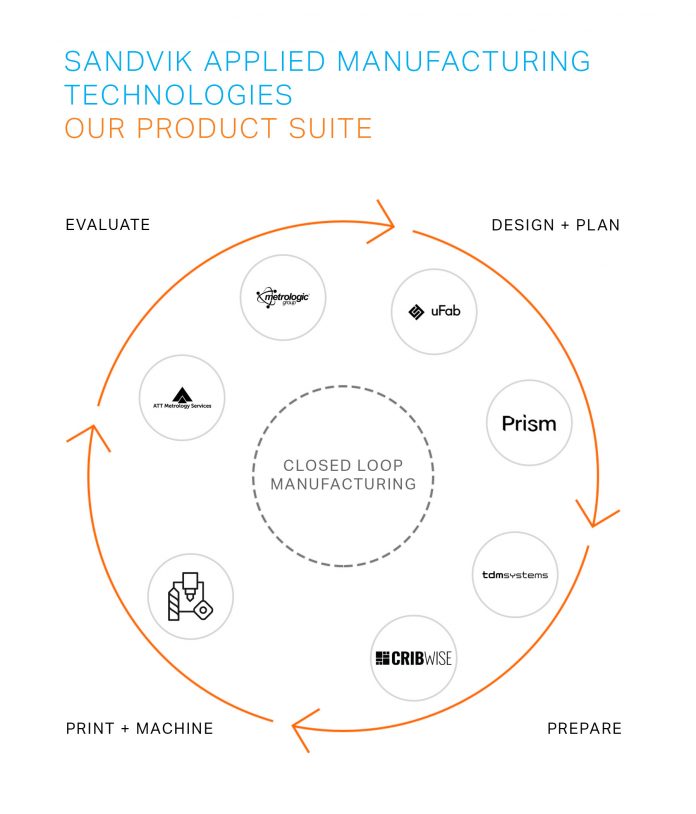

A full suite of state-of-the-art technologies from Sandvik, on display together for the first time at EMO show in Hannover, will allow customers to streamline their production activities across the entire value chain, from design and planning to preparation, machining, and evaluation.

Visitors will be given a glimpse of the machine shop of the future, learning how they can solve real problems in manufacturing by using next generation production systems that combine additive and subtractive technologies with the latest digital optimisation tools. Through the demonstration of real workflows, Sandvik’s technical specialists will demonstrate how manufacturers can ‘close the production loop’ by deploying the perfect combination of processes for the task at hand.

This new approach to production will enable manufacturers to operate more efficiently, with for instance less waste and faster tooling set-up, helping them to become leaner and more productive.

“Sandvik has a proud history as a world-class manufacturer of tools and tooling systems for industrial metal cutting, and more recently also for additive manufacturing services and supply of metal powder alloys,” says Lars Bergström, President Sandvik Machining Solutions.

“Now, these capabilities are supported by a full-circle of digital tools from Sandvik, covering areas like design and planning, preparation, machining and verification. This combination means manufacturers can access a single source of production technologies and expertise, supporting their efforts to become leaner and more flexible, and to gain a competitive edge.”

The expansion into digital solutions and additive manufacturing means customers can choose from a full range of metal cutting tools from Sandvik Coromant, complemented by additive technologies and services as well as digital optimisation tools, meanwhile, help bring these technologies together.

At the design and planning stage, for instance, Sandvik’s data management solutions can be used at the preparation stage to deliver optimised tool management across a spectrum of machines. Meanwhile, the company’s Prism software enables the swift programming of 3-axis machines, delivering easy-to-learn, touch-based CNC programming for 2.5D parts which are built on proven machining “recipes” to ease and expedite the process. Then, Sandvik can help streamline the machining process to fit any operation, regardless of the different types and makes of equipment being used. Finally, advanced digital metrology tools can then be used for verification and evaluation, providing first-class measurement and inspection services of finished products.

In each case, Sandvik will take visitors through an interactive process that illustrates how digital services can deliver value in a real machine shop, along every step of the way.

“This will demonstrate what we mean by ‘closing the loop’ within the production cycle,” says Anders Lindh, President of Sandvik Applied Manufacturing Technologies. “It is about helping our customers deploy next-generation production systems enabled by a full range of materials, machining processes and digital tools. This eco-system of technology and expertise, from a single source, helps drive business advantage. It enables our customers to become faster and leaner, and ultimately more competitive.”

The divisions Sandvik Coromant, Additive Manufacturing and Applied Manufacturing Technologies are part of the business area Sandvik Machining Solutions that employs more than 19,000 people across the world. Revenues for the business area in 2018 stood at 40,343 million SEK, with an operating profit of 9,872 million SEK.

Click HERE for more information, and visit the company’s two EMO stands at Hall 9, Stand F24 (Sandvik Coromant, Applied Manufacturing Technologies and Additive Manufacturing); and Hall 5, Stand B06 (Sandvik Coromant).

About Sandvik Group

Sandvik is a high-tech and global engineering group offering products and services that enhance customer productivity, profitability and safety. We hold world-leading positions in selected areas – tools and tooling systems for metal cutting; equipment and tools, service and technical solutions for the mining industry and rock excavation within the construction industry; metal powder for additive manufacturing, products in advanced stainless steels and special alloys as well as products for industrial heating. In 2018, the Group had approximately 42,000 employees and revenues of about 100 billion SEK in more than 160 countries within continuing operations.

Contact:

Anne Björck | Press & PR, Sandvik Coromant

P: +46 (0) 70 616 32 74