For battery and electronic waste recycling centers, and even battery manufacturers, the mass proliferation of lithium-ion (Li-ion) batteries has presented a unique challenge: how to safely, efficiently and profitably separate and recycle these batteries for disposal and to recover valuable materials such as lithium, copper, iron, nickel, cobalt, and aluminum.

Although Lithium-ion batteries have been around for a long time, destructive recycling simply has not been accomplished on any kind of scale due to the explosive nature of the materials. Unlike other kinds of batteries and even alkaline-based alternatives such as nickel-cadmium (NiCad), Nickel Metal Hydride, Li-ion batteries can induce acid fires, explosions, and thermal runaway, a condition where the release of heat triggers other cells or batteries to rapidly release more heat and VOC gases in a dangerous, quickly escalating cycle.

“Traditionally, the process of recycling Li-on batteries has been described like a scene from Dante’s Inferno. There are acid baths, toxic gases and fumes, and fires and explosions when items are shredded and everyone is walking around in a Hazmat suit. It is a nasty environment to try and process in.” says John Neuens, Sales Director of Milwaukee, WI-based BCA Industries, an established developer and manufacturer of industrial shredding and recycling equipment for a variety of industries, including the battery market.

“The problem is when you put a large item like a battery into a high torque shredder at any moderate speed, you immediately have enormous flammability issues,” adds Neuens. “This is a unique problem for lithium-ion batteries because of the explosiveness and the amount of toxicity that it gives off when it explodes – and they all explode. You have thermal runaway very quickly and atmospheric gases that have to be contained.”

As a result, even large battery companies tend to store lithium batteries in 55-gallon drums without recycling them. As for recycling, Neuens says there are only a few EPA licensed facilities in the United States. Despite being highly regulated, he says it is still “pretty hazardous work to process and reclaim the valuable materials but it can be done safely.”

However, the proliferation of Li-ion batteries is quickly changing the equation. Today, just about every portable electronic device has this type of battery including toys, smartphones, laptops, tablets, cameras, and power tools. Add to this electric vehicles and battery energy storage systems used for storing energy from alternative energy generation sources such as wind and solar.

“Today there is a giant push by industry, including the car industry, to try to recycle those types of batteries and save the valuable, recyclable materials safely,” says Neuens.

Fortunately, there are better, more controlled ways to recycle batteries today that do so with equipment that is safer, less problematic and that does so more efficiently.

Battery Recycling Options

For those less familiar with the process, most shredders turn material into strips. In other words, a one-inch shredder will produce a one-inch-wide strip, but it does not control the length. Standard knife shredders also tend to let the small battery cells slip through unshredded.

To overcome that randomness in size, the traditional way to recycle the material is over a screen with the smaller size material falling through and the bigger material coming back and recirculating through the shredder over and over again until it reaches its desired size. Depending on how each particle orients, it may get cut down further – but it also may not.

The problem is, with a lot of substances like wet battery material, it clogs or “blinds” the screen to a point that it no longer functions. This also slows the process significantly, while increasing maintenance time and costs.

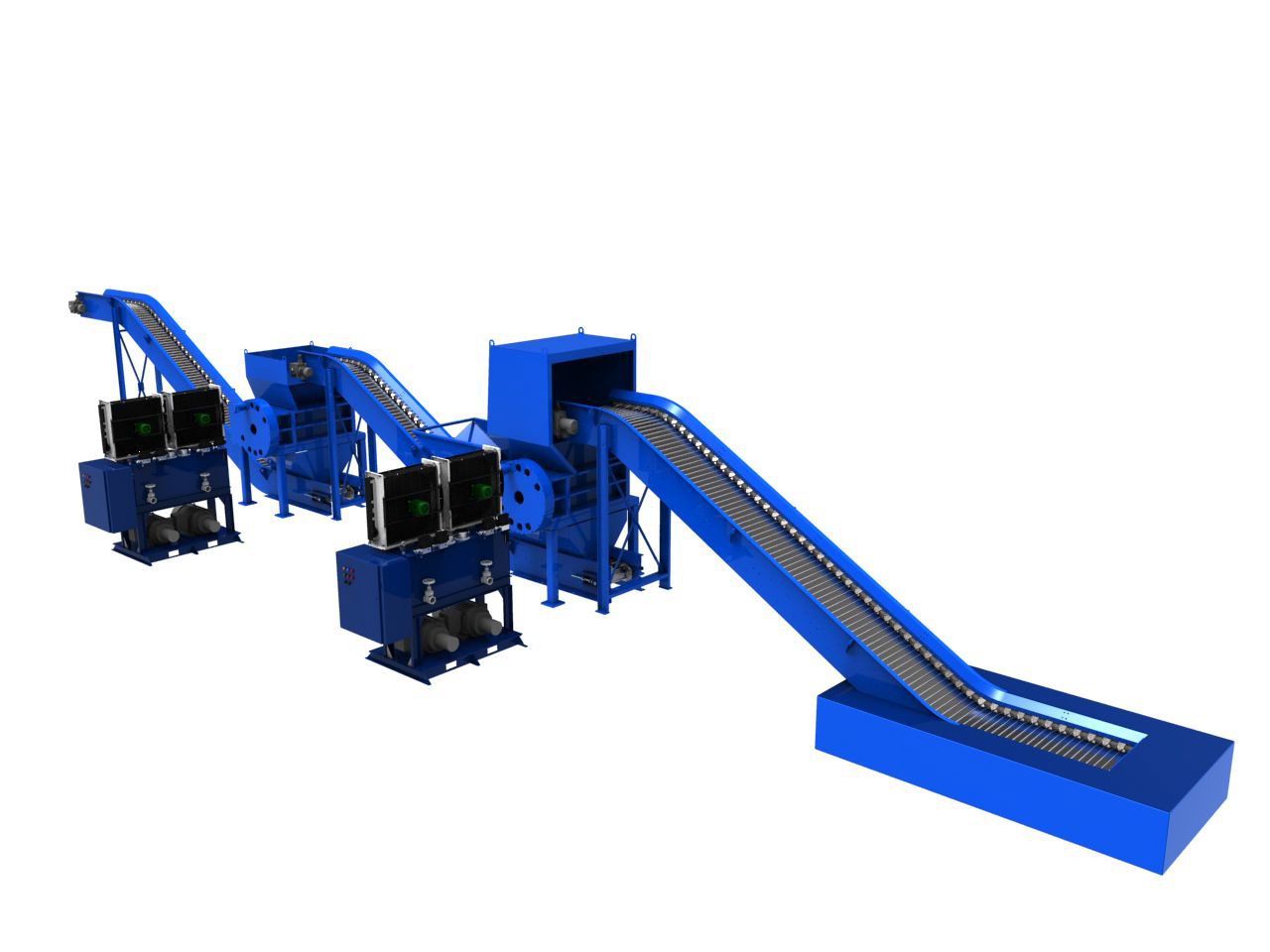

One alternative for Li-ion batteries is to utilize a series of shredders to progressively reduce the size of the material until it’s a desired, uniform size. In some larger battery assemblies, battery recyclers may use several different shredders and then granulators to reach a desired size of less than 3/8-inch, suitable for further processing, says Neuens.

Instead of using many shredders to progressively reduce the size of battery scrap, new shredder “knife” technology can uniformly cut to any size in a single pass and not allow smaller batteries to “slip through” the cutting chamber. This reduces battery scrap down to a reclaimable proportion very quickly while containing thermal run away and fires with a coolant, while requiring significantly less processing, energy use, labor, and maintenance.

One example, BCA’s patented Triplus knife system technology, utilizes a very unique bed knife design in a dual shaft shredder to cut the width of the material of the shredder to any size in a single pass without requiring a screen. The size of the end-product is based on the size and geometry of the rotary and fixed knives as well as their gap distances.

A shredder utilizing this design can produce over 85% correctly sized material in one pass with less than 10% oversized material, according to Neuens. He notes, however, that very large batteries or those with hard metal components such as metal casings or rods are best broken down with another primary shredder first.

With this approach, approximately two to three tons of batteries an hour can be reduced to the proper size for further processing using such a shredder, according to Neuens, who notes that it can also be used in a series with additional shredders if even greater size reduction is required or multiple lines to achieve greater throughput.

Additionally, in place of slow and costly heat tumble drying, often used as part of processing wet battery materials, much faster, less energy intensive solutions have been developed as well.

“Because batteries contain viscous fluids and powdered materials, a drying process must also be utilized before the desired metals can be reclaimed,” explains Neuens. “The common process used, tumble-drying, is very slow, requires tremendous energy, and results in airborne dust that must be controlled and filtered out.”

Luckily, here too, industry innovation has developed a drying system that eliminates the need for tumble-drying, though the specific details of this are proprietary, according to Neuens.

Additionally, the knife system can reduce scrap to the appropriate size with much less energy than typical shearing and grinding equipment. Power efficiency approaches 150% over any standard shredder.

As an example, with this technology, a 50-horsepower single pass shredder can produce the same amount of recyclable product per hour as a standard 100-150 horsepower conventional system. This can reduce recycler energy costs by $1,500-$5,000 per month while producing a more consistently sized product.

The technology is flexible enough to be installed in any size shredder that BCA builds, from 10 HP to 800 HP, from 15” x 12” cutting chamber to 48” x 72” cutting chamber, in both stationary and portable units. So, it can be utilized by both small and large recycling operations on battery sizes from tiny AAA to super-sized Zebra.

The technology is flexible enough to be installed in any size shredder that BCA builds, from 10 HP to 800 HP, from 15” x 12” cutting chamber to 48” x 72” cutting chamber, in both stationary and portable units. So, it can be utilized by both small and large recycling operations on battery sizes from tiny AAA to super-sized Zebra.

With the volume of Li-ion batteries continuing to rise and comprising a greater share of inputs, now is the time for battery and electronic waste recycling centers, as well as OEMs, to investigate solutions that offer greater safety, production capacity, and profitability.

When used with safety precautions such as coolant solutions to control fire and sealed systems with negative air pressure to contain toxic gases, customized end-to-end processes utilizing bed knife technology and improved drying technology can make Li-ion battery recycling and valuable metal reclamation much safer, efficient, and profitable.