Linear motors are widely used in major industrial fields including flat panel display (FPD), semiconductors, automation, medical diagnostics, 3D printing and machine tools. A linear motor is equivalent to a rotary synchronous motor with a ‘rolled-out’ stator and rotor. Instead of producing a torque for rotation, it produces a thrust force along its length.

KOVERY is an ultra-precision motor manufacturer based in Gyeonggi-do, South Korea. Dedicated to continuous R&D, KOVERY is a leading supplier of advanced high-precision linear motor systems.

KOVERY precision motors use patented technology to eliminate or minimise cogging forces that cause velocity ripple and increased bearing wear due to attraction between the stator and the mover parts of the linear motor.

Renishaw’s QUANTiC series of incremental encoders are employed in KOVERY linear motors for commutation and position control. KOVERY also uses other Renishaw metrology products including the EVOLUTE™ absolute optical encoder and the XL-80 laser system for machine calibration. The encoders are critical components that give reliable position feedback in challenging environments.

Challenges

Most linear motors are ‘flat linear motors’ that feature a permanent magnet track under a series of electromagnetic coils (forcer).

Precise control of the forcer is required to enable demanding motion control applications in fields such as semiconductor and FPD manufacture.

Constant velocity control is essential for many advanced industrial processes, but traditional motor designs give rise to cogging forces which generate ripples in the motor velocity.

One option for designers is to use a slotless (ironless) flat motor that provides excellent control at the expense of higher thrust outputs. KOVERY has developed a unique range of motors that minimise cogging forces without sacrificing thrust.

KOVERY President, Kim Houng-joong, introduces the company’s patented technology:

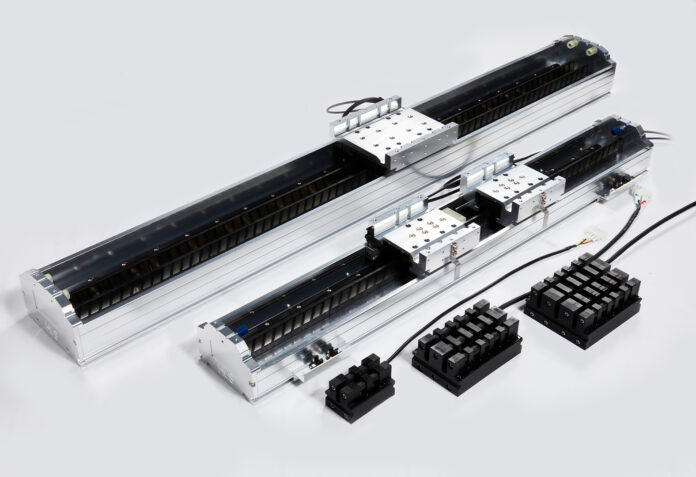

“The linear motors on the market come in various forms. Each design has its benefits but there are always trade-offs. The unique linear motors developed by our company are the first to arrange the permanent magnets in the vertical plane, so that they pass between the pole pieces of the forcer coils.”

“This ensures uniform magnetic flux and an independent magnetic circuit for each magnet track. Our design allows the motor strength to be increased, simply by increasing the number of tracks. The design effectively reduces the normal attractive force between the slotted iron cores and the magnet tracks without sacrificing thrust. In other words, the overall thrust of the motor is increased, and the maximum is at least twice that of a conventional linear motor. Other advantages include reduced weight, increased design freedom, simple assembly and a low cost of ownership.”

Position encoders enable commutation of linear motors to provide smooth motion and position control. Encoders with lower jitter and interpolation error are preferred as they allow more accurate position control and lower velocity ripple.

Encoders for linear motors need two critical design features to work well – a readhead (sensor) cable with a small minimum bend radius and long cable-life to allow for crimping, kinking, and bending on the machine cable track; and a high maximum operating temperature to withstand the expected heat outputs from the motor coils when power is applied.

If the readhead is installed close to the magnetic coils, the encoder must also be able to withstand strong magnetic fields.

Solution

KOVERY uses a range of Renishaw optical encoders for its linear motors – including the advanced QUANTiC optical encoder.

In semiconductor and FPD process equipment applications, KOVERY linear motors are equipped with QUANTiC series encoders featuring 0.2 µm resolution, RTLC40 incremental scale and analogue or digital signal output.

Motors for other applications employ Renishaw’s EVOLUTE absolute optical encoder with RTLA50-S linear scale.

Mr. Houng-joong continues: “KOVERY’s linear motors offer a range of specifications, and there are more than a dozen different stroke lengths alone. Sometimes, it is necessary to provide customized products with strokes up to several metres. We also expect that market demand for longer-stroke linear motors will increase. The QUANTiC encoder’s RTLC40 steel tape scale is supplied on a convenient reel, which allows us to cut the exact length required for each motor – improving our operation flexibility. In addition, the short delivery lead times and excellent cost performance are all factors. Renishaw’s encoders have improved the competitiveness of our products.”

Advantages of QUANTiC encoders include compatibility with industry-standard digital or analogue outputs, wide installation and operating tolerances of ±0.3 mm (rideheight) and ±0.9° (yaw), high operating speeds of up to 24 m/s, low Sub-Divisional Error (SDE) down to ±80 nm, flexible single-shielded cables for EMI protection, and an integrated set-up LED to aid installation.

Enhanced diagnostic data can be accessed via the optional Advanced Diagnostic Tool ADTi‑100 and free ADT View software. The ADTi‑100 is ideal for difficult installations, in-field diagnostics and fault finding.

In particular, the set-up LED and exceptionally wide installation tolerances of the QUANTiC encoder enable a quick and intuitive installation process, lowering machine build costs and reducing machine downtime when servicing. Furthermore, the low SDE and high resolution of the QUANTiC encoder improves linear motor accuracy and enables smoother motion control due to reduced velocity ripple.

As Mr. Houng-joong explains: “When choosing an encoder system, in addition to the encoder specifications required for our customer’s application, we also consider the installation difficulty and reliability in our production environment. Orders from equipment manufacturers require very short lead times – from the receipt of an order, we often have only 3 to 6 months for design, manufacturing, testing, and delivery.”

“The quick and easy installation of parts is absolutely one of the key factors for punctual delivery. QUANTIC encoders have wide installation tolerances that enable faster installation. Also, by monitoring the colour of the set-up LED on the readhead, we can quickly determine if the signal strength is up to standard and whether the installation is successful. These features save time, reduce costs and give us great confidence.”

Renishaw’s EVOLUTE absolute encoder features many of the same benefits of the QUANTiC series, including wide installation tolerances and good dirt immunity. Enhanced diagnostic data is also available through the Advanced Diagnostic Tool ADTa-100 hardware and ADT View software.

KOVERY tests and calibrates its motors prior to leaving the factory using Renishaw’s XL-80 laser system for machine calibration and quality control. These systems are fast, extremely accurate with linear measurement accuracies of 0.5 ppm, lightweight and portable.

“Our customers are mostly precision equipment manufacturers, who have demanding quality requirements, so motors need to be strictly verified before they leave our factory. The linearity, straightness and squareness of each linear motor is measured using Renishaw’s XL-80 laser interferometer. Dynamic measurements are also performed, including analysis of the velocity ripple.

For product testing, the XL-80 system is quick to set-up and easy to use – it’s undoubtedly a great choice,” says Mr. Houng-joong.

Results

Renishaw’s encoder products and laser calibration systems have enabled KOVERY to build cutting-edge linear motors for advanced process machinery in fields such as semiconductor manufacturing. The partnership between Renishaw and KOVERY continues to support the latest linear motor developments.

Mr. Houng-joong concludes: “We focus on the development of ultra-high-precision and high-speed linear motors. It is impossible to have a thorough understanding of every component. Renishaw has done a very good job in after-sales support; they often communicate closely with our development team, provide relevant training where required, and have solved many application problems for us.”

About Kovery Inc

KOVERY is an ultra-precision motor manufacturer dedicated to continued R&D and the development of original technology. Its strategic objectives are to contribute to the growth and prosperity of domestic industry and to enter the global marketplace through the commercialization and mass production of ultra-precision motor systems. To date, the company has applied for over 200 motor-related patents.