The future development impetus of the internal combustion engine will focus on the reduction of emissions. This is dependent on fuel consumption, which in turn is determined by the internal engine friction. The goal of form honing is a form optimized cylinder bore under operating conditions.

Abraham Pizano, Managing Director Gehring-Mexico, presented Gehring’s CO2 emissions reducing technology solutions at a recent technical forum in Mexico to an audience of leading technical and business professionals, from a wide variety of industries, including automotive, aerospace and industrial.

The conference is one of the region’s top technical events for manufacturing, featuring the latest in global manufacturing trends, including processes, applications, materials and advanced techniques.

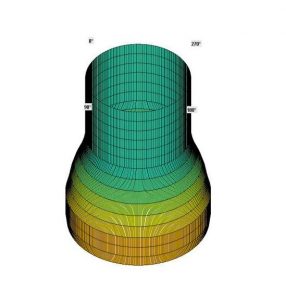

Gehring developed a surface finishing process for ICE’s which does not target a cylindrical bore shape. The bore shape is based on the distortions of the geometry under operating conditions of the engine. Through the means of form honing the reverse shape will be produced so that in running conditions, a cylindrical shape exists. The deformation in the operating condition depends on static assembly distortions and thermal cylinder distortions.

This technology can be subdivided into two process variations, form honing light and form honing professional. Form honing light simulates thermal distortion by creating different tapered shapes. The thermal expansion due to the higher taper in the top dead center leads to a cylinder bore which has to be honed to a smaller size at the top and a larger size at the bottom. Thus, the piston shirt has less contact with the bore. This results in significantly less friction.

The conical shape is generated by feedback controlled stroke displacement with higher stock removal in the lower bore section due to increased contact time of the abrasives.

The dynamic electro-mechanical feeding changes the radial expansion position of the honing stones during the stroke movement according to the form and improves herewith the previous conical shape.

The dynamic electro-mechanical feeding changes the radial expansion position of the honing stones during the stroke movement according to the form and improves herewith the previous conical shape.

These process components assure the reliable process of round non-cylindrical tapered bores within the known cycle times. Form honing has been already integrated globally into mass production scenarios. Application of form honing light technology has shown that significant improvements in emissions reductions are possible.

Form honing professional not only optimizes the local piston clearance, but also compensates for cylinder deviations from static and thermal distortions. That means that in running conditions round and straight bores can be achieved. Ring tension is reduced which results in adaptive friction and C02 reductions.

The non-cylindrical shape deviations can be defined through CAE assessments or torque plate bracing and tempering. In order to be able to implement form honing professional, innovative processing hardware like special honing tools with independent actuated abrasives, a piezo feeding system, a shape adaptive control and a spring loaded finish honing tool, is necessary.

The shape data for the cylindrical deviations will be converted for every single cylinder of the engine using the form honing control. This dynamic process interaction between the feeding system, shape and the form honing tooling creates an optimal result.

The shape data for the cylindrical deviations will be converted for every single cylinder of the engine using the form honing control. This dynamic process interaction between the feeding system, shape and the form honing tooling creates an optimal result.

Form honing professional has been implemented by customers for small production batch scenarios. The process produces cylinder deviations and surface finish profiles with high reproducibility and economical processing times. The process delivers free shapes and surface profiles with high reproducibility to conditions that still conform to cycle times.

The advantages of form honing have been recognized by engine manufacturers and have been implemented in numerous production lines on Gehring honing machines worldwide. Further series applications are in preparation.

About Gehring

For more than 90 years, Gehring has been the leader in the domain of honing technology, supplying cutting-edge surface finish technology solutions for internal combustion engines, gears and numerous other industrial applications. As a global technology leader, the company is represented internationally in key markets in the automotive and supplier industries, hydraulics and pneumatics, as well as aerospace sector.

The Gehring product portfolio ranges from individual honing stones to honing tools as well as gauging and automation solutions right up to integrated honing systems. Digital applications, services and innovative technologies in the areas of honing, laser structuring, roughening and coating complete the portfolio.

With standalone made-to-measure solutions for stator prototype development and small-scale series production, as well as fully automated new system solutions for electric motor production lines, copperING‘s product portfolio complements that of its new partner Gehring. The Gehring group therefore offers the full gamut of technologies for vehicle drives – from conventional solutions to hybrid technologies and even integral electrification.

The Gehring Group with approx. 800 employees, is headquartered in Ostfildern, Germany, and has additional locations in Naumburg and Wernigerode, Germany, as well as in the USA, China, India, Italy, UK, France, Brazil and Mexico.

Gehring L.P.

24800 Drake Road

Farmington Hills, MI 48335

Jaqueline Fette | Director of Marketing

Tel: +1 248 427-3943

Cell: +1 248 954 8383

E-Mail: jaqueline.fette@gehring-group.com