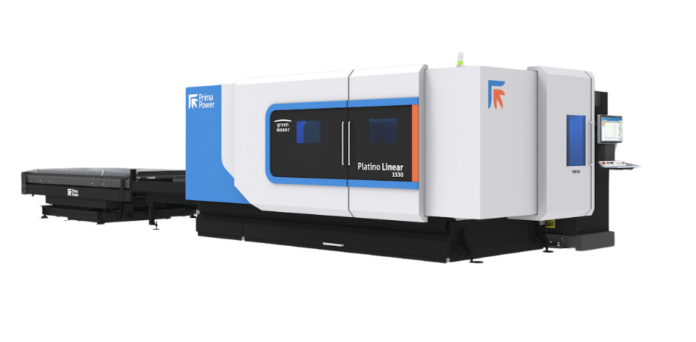

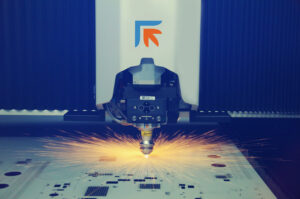

The Platino Linear offers significant advantages for the metalworking industry, particularly in the fabrication of metal parts and components. Its superior cutting quality and speed are essential features that enhance metal fabrication processes. The machine’s Adaptive Cut feature ensures optimal cutting quality across various metal types and thicknesses. This adaptive laser head capability allows for versatile and precise processing, crucial in producing a wide range of metal components. The Platino Linear’s high speed and acceleration, supported by its lightweight yet rigid aluminum carriage, enable rapid and efficient metalworking operations. Additionally, the machine’s compact design, occupying 22% less space than others in its category, and maintenance-free linear drive system contribute to reduced downtime and increased operational efficiency.

The innovative cantilever architecture and open-design cabin provide complete access to the work area, while the synthetic granite frame delivers exceptional vibration absorption and thermal stability, guaranteeing reliable performance. An aluminum carriage minimizes the weight of moving components without sacrificing rigidity, ensuring high accuracy. Features like Smart Cut and Gas Mixer Cut optimize operations, reducing cycle times by up to 30% and enhancing cutting quality. ECO-TOUCH Cut reduces gas consumption by up to 40%, contributing to sustainability. Adaptive Cut adjusts focus and beam diameter for different materials automatically. The Safe Impact Protection System prevents damages from collisions, ensuring reliability. With these features, Platino Linear offers efficient, sustainable, and advanced production at a competitive price, ideal for any business seeking quality and cost-effectiveness.

The innovative cantilever architecture and open-design cabin provide complete access to the work area, while the synthetic granite frame delivers exceptional vibration absorption and thermal stability, guaranteeing reliable performance. An aluminum carriage minimizes the weight of moving components without sacrificing rigidity, ensuring high accuracy. Features like Smart Cut and Gas Mixer Cut optimize operations, reducing cycle times by up to 30% and enhancing cutting quality. ECO-TOUCH Cut reduces gas consumption by up to 40%, contributing to sustainability. Adaptive Cut adjusts focus and beam diameter for different materials automatically. The Safe Impact Protection System prevents damages from collisions, ensuring reliability. With these features, Platino Linear offers efficient, sustainable, and advanced production at a competitive price, ideal for any business seeking quality and cost-effectiveness.

Prima Power offers tailored automated solutions, all available for the Platino Linear, enhancing efficiency and productivity by minimizing manual intervention and optimizing space. The Compact Server features dual storage units and consolidates components onto an automatic pallet changer, maximizing space utilization. The Combo Tower Laser automates material flow with shelving groups and customizable loading units. The PSR 2D System ensures precise stacking and uninterrupted operation. The Night Train FMS® Storage System serves as material storage and buffer, with intelligent cassette management for real-time monitoring. Prima Power’s commitment to personalized solutions evolves alongside customer needs, emphasizing modular and expandable automation to meet dynamic requirements effectively, encapsulated in our brand promise “Evolve by integration.”

About Prima Power

Prima Power provides businesses of all sizes with targeted dynamic technologies that enhance profitability in sheet metal working. We build our offer on a full range of modular solutions, using our distinctive customer-centered approach and longstanding knowledge in engineering systems and machinery for sustainable, efficient manufacturing — all based on a unique history of technological integration.

Prima Power’s range of technologies is one of the widest in the industry: 2D and 3D laser machines for cutting, welding and drilling, punching machines, combined punch-laser and punch-shear systems, press brakes, panel benders, robotic bending cells and flexible manufacturing systems. Prima Power is the brand for sheet metal manufacturing of Prima Industrie, the industrial innovation group with 1,900 people, 15,000 installations, 7 plants, and annual revenues of over 500 million euros.