NICKEL PLATED HOISTS SUITABLE FOR HYGIENICALLY CRITICAL AREAS

Selected models from the J D Neuhaus range of air operated hoists and trolleys are now available for clean room operations and other specialist applications that also require hygienic working conditions. These include chemical and pharmaceutical production establishments, together with the food and drink industries covering all aspects of both handling and manufacture.

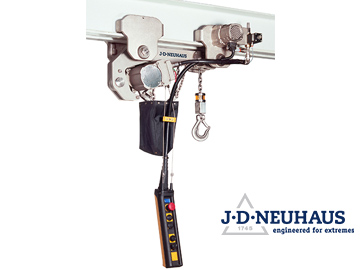

With a plating thickness of 25 µm, the hoists ensure resistance to environmental humidity as well as providing a good general corrosion resistance. The typical component parts of the hoist units that are subject to the nickel plating process include the lift/lower motor together with gearbox and the main centerpiece body. Where the hoist is trolley mounted for overhead rail operation, the trolley body and both driving and traverse motors are also nickel-plated.

Further protective features also available include the provision of stainless steel options for the top suspension hook, both the load hook and sleeve, together with the lift/lower chain mechanisms and 12 meter capacity chain bag. Specification of the stainless steel hook and chain does limit the lift capacity to 0.75 metric tons however. Further options include plastic chain boxes suitable for 3, 6 and 12 meter chain lengths together with a 12 meter galvanized chain box.

A further positive aspect of the products is the fact that the lift motor does not require lubrication and all hoists are classified as explosion protected to comply with Directive 2014/34/EU [Equipment & Protective Systems Intended for use in Potentially Explosive areas (ATEX)]. The hoists are also classified as capable of 100% duty rating with no downtimes.

The models currently available in the nickel-plated range include: the Profi TI hoists with 0.5 and 1 metric ton lift capacities, together with a big-bag handling unit with a rated 1 metric ton lift. A low headroom trolley hoist of 1 metric ton capacity is also available, which is designed for operation in areas subject to low headroom capacity. Where Profi hoists are utilized with trolleys for overhead rail mounting, both manual operated (type LN) and motorized (type LM) trolleys can be provided which have also been subject to appropriate nickel-plating treatment for use in hygienically critical areas.

About J D Neuhaus

At its Witten plant, J.D. Neuhaus produces pneumatically and hydraulically-operated hoists and crane systems with 170 employees. Thanks to this globally unique specialization, we are not only recognized experts in this field, but also the world market leader with customers in more than 90 countries around the globe.

Starting with the development and manufacture of our products, we place great value on ecological compatibility. Long service life and recyclability already make an important contribution towards relieving the environmental burden. Furthermore, our production has been adapted to minimize energy consumption, emissions, sewage and waste; it also uses environmentally-compatible production processes and materials. Resources are used sparingly and waste is recycled wherever possible. We have also made environmental protection a permanent feature of our employee training courses. Since 2009, we have been certified according to ISO 14001 by the TÜV Rheinland Technical Control Association for our comprehensive environmental management system.

Our quality management system covers all our processes, from planning and design through to production and customer service. It is also certified by the TÜV Rheinland according to ISO 9001.

For more information, visit www.jdngroup.com.