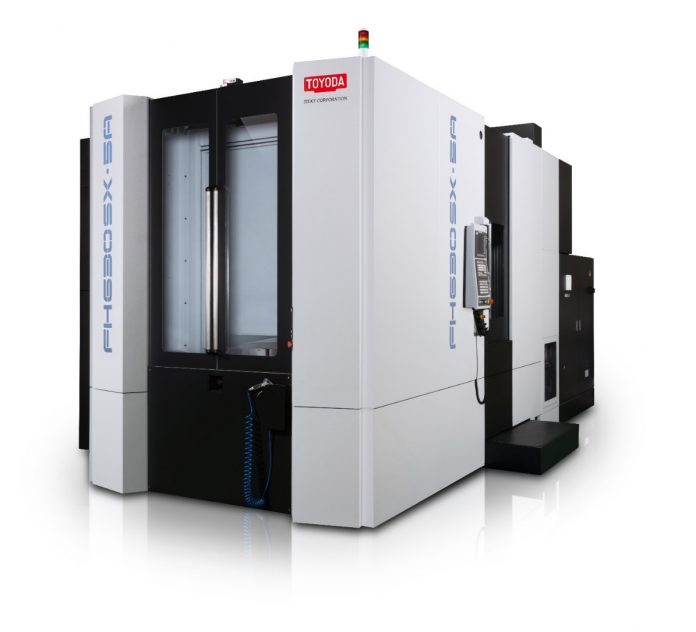

JTEKT Toyoda Americas Corporation is excited to introduce its’ newest addition to the 5-Axis family, the FH630SX-i 5-Axis Horizontal Machining Center. The machine combines best-in-class performance, high torque and simultaneous 5-Axis machining – achieving complex part machining and multi-surface processing all within one setup.

“From the highly rigid platform to the flexible swivel spindle, our newest 5-Axis addition combines the stability and versatility that shop owners look for and need with complex cutting production”, says Graham Roeder, National Product Manager at Toyoda. “By taking full advantage of the performance reliability and machining scope of the Toyoda FH630SX-i 5-Axis, shops have the ability to dramatically increase profit opportunities, while keeping costs, time, fixture preparation, and waste at a minimum – reducing the risk of improper setup. Additionally, combining the FH630SX-i 5-Axis with 4-Axis machines on a shared RGV system allows shops to increase performance – enhancing autonomous production.”

Toyoda built upon its renowned highly rigid spindle design, adopting a tilting swivel motion to enable exceptionally efficient processing of large workpieces. For increased flexibility, the machine is capable of travelling 12” past the pallet centerline in the vertical orientation. Whether cutting aluminum or titanium, the FH630SX-i 5-Axis features spindle speed flexibility due to the interchangeable spindle cartridge supporting the special-purpose optional 8,000 RPM, 107 HP high-torque spindle, or standard 15,000 RPM, 74 HP high-speed spindle. Both spindles are designed with Toyoda’s patented replaceable taper for easy repairs and high maintainability. The tilting spindle also comes with a robust C-axis drive train and an enlarged C-axis swivel range of 230 degrees for better workpiece access. Furthermore, the base, which supports the spindle, minimizes displacement from external forces that affect processing accuracy; enduring huge cutting forces in addition to the inertial force of feeding acceleration/deceleration.

Toyoda built upon its renowned highly rigid spindle design, adopting a tilting swivel motion to enable exceptionally efficient processing of large workpieces. For increased flexibility, the machine is capable of travelling 12” past the pallet centerline in the vertical orientation. Whether cutting aluminum or titanium, the FH630SX-i 5-Axis features spindle speed flexibility due to the interchangeable spindle cartridge supporting the special-purpose optional 8,000 RPM, 107 HP high-torque spindle, or standard 15,000 RPM, 74 HP high-speed spindle. Both spindles are designed with Toyoda’s patented replaceable taper for easy repairs and high maintainability. The tilting spindle also comes with a robust C-axis drive train and an enlarged C-axis swivel range of 230 degrees for better workpiece access. Furthermore, the base, which supports the spindle, minimizes displacement from external forces that affect processing accuracy; enduring huge cutting forces in addition to the inertial force of feeding acceleration/deceleration.

Click HERE to learn more about Toyoda’s 5 axis series.

FH630SX-i 5 Axis Horizontal Machining Center Specifications:

Pallet Size

Table Index

Axis Travel (X, Y, Z)

Max Workpiece Swing

Max Workpiece Height

Max Work Load on the Pallet

Spindle Output Torque

Available Spindle

Rapid Feed Rate (X, Y, Z)

Tool Storage Capacity

24.8″ x 24.8″ (630 mm x 630 mm)

Full NC Table (360,000 positions)

31.5” (800 mm), 33.46” (850 mm), 41.33” (1,050 mm)

46.06” (1,170 mm)

62.99″ (1,600 mm)

3,306 lb (1,500 kg)

802 ft-lb (1,088 Nm)

CAT#50 107HP 8,000 RPM (1,088 Nm)

CAT#50 74HP 15,000 RPM (526 Nm)

2,362 ipm (60 m/min)

60 Standard

About JTEKT Toyoda Americas Corp.

JTEKT Toyoda Americas has been a premium global machine tool leader for more than 70 years, offering top quality products, services, and CNC parts to the United States, Canada, Latin and South America. Toyoda’s extensive lineup includes cam & crank grinding, horizontal machining centers, vertical machining and turning centers, cylindrical grinding machines, and automation systems all built to the highest quality standards with thoughtful engineering and expert craftsmanship. We understand tight tolerances, superior speed, and peak performance.

Email Graham Roeder, National Product Manager for Horizontals HERE with questions regarding Toyoda’s Horizontal Series.

Click HERE to see first-hand the FH630SX-i’s simultaneous 5-axis machining – achieving complex parts and multi-surface processing all within one setup.

JTEKT Toyoda Americas Corporation

316 W. University Drive

Arlington Heights, IL 60004

Kathy Adolf, Marketing Strategist | Product Development

P: (847) 550-9301