Renegade Parts Washer Cleans Without Solvents to Lower Environmental Impact, Increase Automation, and Reduce Labor Costs for Screw Machine, Fastener, and Small Components Industries.

Renegade Parts Washers announces new automatic top load parts washing system with rotating tumbler operation for batches of small machined parts, fasteners, components, bolts, and nuts for screw machine or fastener industries and more.

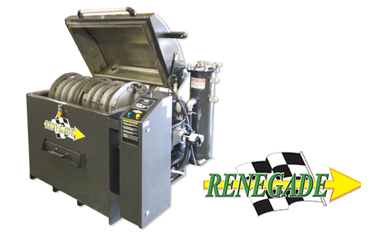

The Renegade Model TLT Dual 1615 Tumbler Parts Washer Solvent-Free System functions like a dishwasher to clean small parts and components covered with grease, oil or lubricants. The wash zone features dual geardriven rotating cylinder baskets combined with spray nozzles to deliver high pressure force and high temperature cleaning performance. A range of capacities and single or dual basket configurations are available.

The Renegade Model TLT Dual 1615 Tumbler Parts Washer Solvent-Free System functions like a dishwasher to clean small parts and components covered with grease, oil or lubricants. The wash zone features dual geardriven rotating cylinder baskets combined with spray nozzles to deliver high pressure force and high temperature cleaning performance. A range of capacities and single or dual basket configurations are available.

The Renegade Model TLT Dual 1615 Tumbler Parts Washer Solvent-Free System functions like a dishwasher to clean small parts and components covered with grease, oil or lubricants. The wash zone features dual geardriven rotating cylinder baskets combined with spray nozzles to deliver high pressure force and high temperature cleaning performance. A range of capacities and single or dual basket configurations are available.

Automation features include PLC Programmable Wash Cycle Timer and Heater Timer. Increased automation allows the operator to multi-task, and reduced labor costs impact cost of operations. Rugged stainless-steel construction means low maintenance but delivers high performance batch after batch. Renegade Parts Washers are designed to work with specially formulated, solvent-free detergents for maximum cleaning without residue buildup and lower environmental impact.

Automation features include PLC Programmable Wash Cycle Timer and Heater Timer. Increased automation allows the operator to multi-task, and reduced labor costs impact cost of operations. Rugged stainless-steel construction means low maintenance but delivers high performance batch after batch. Renegade Parts Washers are designed to work with specially formulated, solvent-free detergents for maximum cleaning without residue buildup and lower environmental impact.

About Renegade Parts

Washers The Renegade Product Lines of Parts Washer Equipment and Parts Washer Detergents is manufactured and sold by Service Line, Inc. in Reedsburg, Wisconsin. Founded in 1996, the product lineup includes the standard Renegade automatic top load and front load parts washing systems, manual parts washers, and the Renegade Industrial Series of automatic top load and front load aqueous part washing systems, rotary parts washers, immersion parts washers, and pass-through parts washers, all available with value-added configurations that consider the operating costs of the entire cleaning production cycle, including advanced automation, product handling, worker safety, and environmental impact. Renegade Detergent, Soaps and Additives developed for parts washer systems are the solvent-free, high performance cleaning solution with additional health benefits. Additional Service Line, Inc. products include Hanen Automatic Solar-Powered Cattle Feeders and full metal fabrication services are manufactured in Reedsburg, Wisconsin, and are available in the U.S. and International markets.