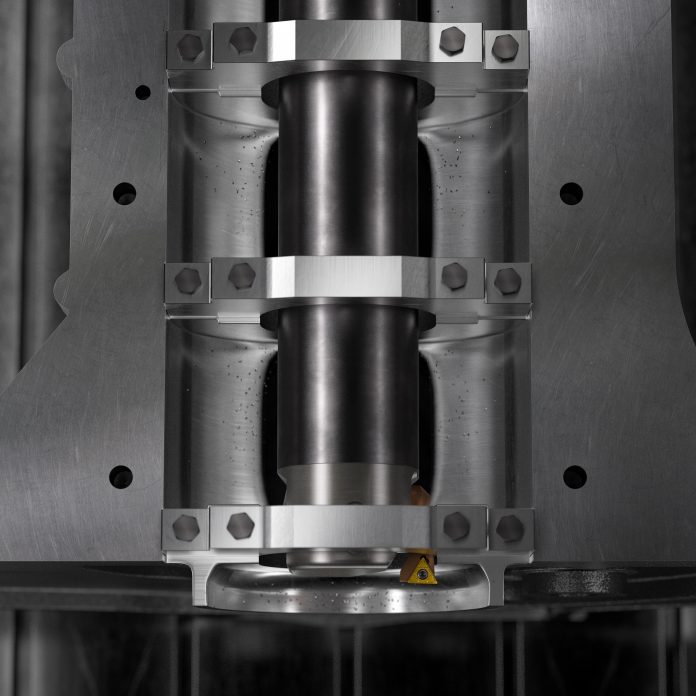

Cutting tool and tooling system specialist Sandvik Coromant is releasing a new-generation CoroBore® 825 dampened fine-boring tool. The system makes use of Silent Tools™ technology, with dampers dimensioned specifically to suit every adapter size in the assortment and deliver maximum performance for the user. This solution not only elevates process security where vibration issues are frequently encountered, such as when machining with long overhangs, but also improves productivity since cutting data can be increased substantially.

Among the principal updates in the latest-generation tool is the change of boring head material from steel to aluminum. In addition, the head has been shortened so that the damper comes closer to the cutting edge, which is beneficial for process stability.

“Internal channels are utilized to deliver coolant directly to the cutting edge, which is another factor that contributes to improved surface finish, higher penetration rates and greater process security,” says Jenny Nilsson, Global Product Manager at Sandvik Coromant. “The new generation of tools will provide optimum performance and stability with one standard adaptive item on the machine-tool side, to bridge the tool into a steep taper, HSK or Coromant Capto® spindle. Further extensions will reduce stability and performance.”

The CoroTurn® insert carriers for the new tools have entering angles at 92–95°. This design increases stability due to reduced tool assembly deflection, making it possible to approach the bottom of a blind hole without engaging a greater part of the cutting edge.

CoroBore® 825 is ideal for all fine-boring applications, covering diameters from 19 to 167 mm (0.748 to 6.575 inch), while a new assortment of cartridges can be utilized for back-boring applications. During back boring, the same internal coolant flow to the cutting edge is offered as in conventional boring.

For ease, the complete tool, comprising adapter and insert carrier, is delivered as a kit with a single product code.

Click HERE for more information.

About Sandvik Coromant

Part of global industrial engineering group Sandvik, Sandvik Coromant is at the forefront of manufacturing tools, machining solutions and knowledge that drive industry standards and innovations demanded by the metalworking industry now and into the next industrial era. Educational support, extensive R&D investment and strong customer partnerships ensure the development of machining technologies that change, lead and drive the future of manufacturing. Sandvik Coromant owns over 3100 patents worldwide, employs over 7,900 staff, and is represented in 150 countries.

Editorial inquiries

Angela Roxas, PR & Sponsorships | Sandvik Coromant

P: (201) 294-9160