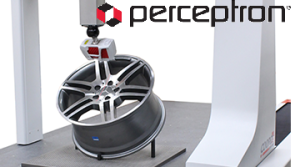

PERCEPTRON LAUNCHES EXPERT CMM SOLUTION – A HYBRID COORDINATE MEASURING MACHINE WITH TOUCH SOFTWARE ALLOWING FULLY AUTOMATED PRODUCTION METROLOGY USING LASER SCANNING TECHNOLOGY

The Expert CMM package includes the CMM, motorized probe head, touch-probe, ScanR™ laser sensor, and sensor change rack and touch-metrology software with point-cloud.

Perceptron has launched a CNC multi-sensor CMM solution that seamlessly integrates touch-probe and laser scanning functionality into a single measuring station, operated exclusively by touch software. The Perceptron EXPERT CMM offers full point-cloud geometric feature extraction and direct comparison to CAD for automated inspection of production parts. The automatic scanning package price is comparable to lower accuracy manual portable arm measuring solutions.

Perceptron has launched a CNC multi-sensor CMM solution that seamlessly integrates touch-probe and laser scanning functionality into a single measuring station, operated exclusively by touch software. The Perceptron EXPERT CMM offers full point-cloud geometric feature extraction and direct comparison to CAD for automated inspection of production parts. The automatic scanning package price is comparable to lower accuracy manual portable arm measuring solutions.

Laser scanning has proven its role in manufacturing over past years with the increased application of manual portable arm scanning systems. These labor intensive systems are more suitable for reverse engineering and one-off inspection tasks. Perceptron has harnessed its expertise in automated inline production metrology for global vehicle production by widening the reach of its industry-leading scanning technology for general manufacturing. Software complexity of traditional measuring equipment mandates its use by metrology experts; Perceptron’s TouchCloud™ software module add-on for its TouchDMIS™ software puts the EXPERT into the solution, and significantly reduces the necessary user skill level.

Full feature extraction from point-cloud rather than rendered .STL format provides for faster and more accurate measurements. Part features can be touch-probed or laser-scanned depending on feature type and tolerance.

The Perceptron ScanR™ scanner is available with a standard red laser line and optionally with a green laser to significantly extend dynamic range, allowing scanning of both highly reflective and black parts.

EXPERT CMM can also be supplied with any size and configuration CMM from the Perceptron Coord3 CMM range or retrofitted to existing customer-installed CMMs.

Perceptron’s Vice President of Global Marketing, Keith Mills says “Perceptron is a leader in supplying automated metrology using robotic technology for the automotive industry in their most demanding production line applications. The EXPERT CMM package further extends the reach of our technology into global manufacturing.”

About Perceptron

Perceptron supplies a comprehensive range of automated industrial metrology products and solutions to manufacturing organizations for dimensional gauging, dimensional inspection and 3D scanning. Products include 3D machine vision solutions, robot guidance, coordinate measuring machines, laser scanning, and advanced analysis software. Automotive, aerospace and other manufacturing companies globally rely on Perceptron’s metrology solutions to assist in managing their complex manufacturing processes to improve quality, shorten product launch times and reduce costs. More than 900 systems, 12,000 Perceptron measuring sensors and over 3,000 COORD3 coordinate measuring machines are in active daily use worldwide. Headquartered in Plymouth, Michigan, Perceptron has approximately 360 employees worldwide, with operations in the Brazil, China, Czech Republic, France, Germany, India, Italy, Japan, Singapore, Spain and the UK. For more information, please visit www.perceptron.com.