Meltio, a disruptive laser metal deposition technology manufacturer – has today taken a giant step towards facilitating the use of its unique metal 3D printing solutions.

In its vision to accompany and be the reliable solution for industries around the world to adopt Meltio’s metal 3D printing solutions that reduces costs and improves manufacturing processes, the Spanish multinational has today presented two new innovations to increase the reliability of metal part manufacturing for creating accuracy parts: the Meltio Horizon software and new Laser Calibration System.

Both technological solutions developed by Meltio’s engineering team represent a further step in the company’s strategy to eliminate the barriers that have prevented metal additive manufacturing from having a significant presence in many industrial sectors. Meltio now becomes the perfect ally for these industries.

As CEO of Meltio, Ángel Llavero is excited about these two new innovations to help industries around the world using Meltio’s wire-laser metal 3D printing technology:

“We have developed the Meltio Horizon software and the Laser Calibration System with the aim of facilitating the use of Meltio’s metal 3D printing technology for industries around the world. It should be noted that metal additive manufacturing has historically been associated with complex and expensive software, limited to the use of very few people because it was very specialized. At Meltio, with the launch of our new software, we facilitate and shorten the learning time for you to democratize metal 3D printing so that your software is accessible and easy to use for many different profiles within a company. The Laser Calibration System will give industrial companies a new tool to be able to work with guaranteed reliability in the creation of their metal parts”.

Meltio Horizon

Meltio Horizon

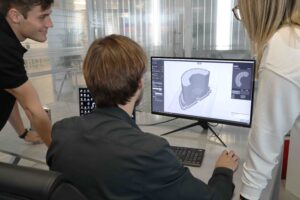

Meltio Horizon is a proprietary toolpath generator software that ensures a fully tailored customer experience around its plug-and-play metal 3D printer, the Meltio M450, with its own unique features and custom-developed Meltio print and material profiles included. The new software solution is tailored to use the laser wire metal deposition process with the Meltio M450. Up until now, Meltio users have been reliant on using 3rd party FFF slicers to prepare toolpaths for the Meltio M450.

In addition to traditional slicing parameters used in FFF software such as layer height, line width, print speed, and support materials, the new Meltio Horizon provides tailor-made access to Meltio’s laser-wire process, and material-specific parameters such as laser power, dual wire, and hot wire settings.

With the Meltio Horizon software, all of the material-related settings are directly in the slicing software, allowing for full control and just a single profile. This also allows us to create more specialized printing profiles, with the power to directly control the laser and hot wire on a “per slicing feature” basis, rather than being set for the full part.

This slicer is currently only compatible with the Meltio M450 metal 3D printer. For Meltio Engines (CNC and Robot Integration), the company is currently working on developing its open software ecosystem partnerships that allow the generation of 5 Axis G-Codes.

Features of the Meltio Horizon:

Features of the Meltio Horizon:

- Easy to use: Only settings relevant to Meltio’s laser-wire metal 3D printing process are available. Specific settings are explained to make getting started with the printing process as smooth as possible

- Cost calculation: Easily configure your printing cost model and automatically calculate the cost per part in each project

- Future proof: Building a dedicated platform for toolpath generation specific to Meltio enables to expand the scope of our service in the future

- Tailor-made to laser-wire: Made to measure for Meltio’s wire-laser metal 3D printing process as well as it also comes with built-in profiles for the Meltio Materials

- Combined material profile: Previously split between printer and slicer – now all is in the slicer

- Custom gas profile: Configure your gas source and cost directly within Meltio Horizon. Flow rates are defined within each material

- Custom build plates / work spaces: Select the right substrate right from the slicer depending on the part size. Build plates can be defined by the user and stored as presets. The machine workspace adjusts automatically, notifying the user if a selected build plate is too small

- Automatic updates: Updates of the Meltio Horizon and new printing parameters are available directly through the slicer. New Meltio Materials and printing profiles will be released periodically

- 2D and 3D previews: To provide a good insight into the model to be printed, the Meltio Horizon provides both a 2D and a 3D preview of the toolpath. The 2D plan vision allows for easy inspection of the toolpath throughout the model

- Project files incorporated: The complete project file, consisting of the model file, workspace, build plate as well as gas and material profiles can be conveniently stored and shared.

Laser Calibration System

In addition, Meltio has launched a new Laser Calibration System as an accessory (kit) to aid the reliability and ease of use of Meltio’s machines, ensuring a faster and more reliable print process to enhance user experience.

The Laser Calibration System allows Meltio users to calibrate Meltio’s multi-laser deposition head accurately and effortlessly on all three of its metal 3D printing solutions. The system consists of a laser alignment camera that has to be placed under the printhead as it allows for a clear view of the focus point of the lasers. The camera is controlled using a portable controller, which also comes included in the kit as well as a software specifically designed to filter the camera image and guide the user to focus each laser on the most optimal point.

The addition of this new kit is a major advance over the current state of general metal Additive Manufacturing (AM) solutions. Manual laser alignment remains possible but will require a very experienced operator to match the consistency of the laser alignment kit.

Meltio’s multi-laser metal 3D printing technology is based on the use of six lasers pointing to a mutual point to melt the welding wire that is fed through the center of the deposition head. The lasers generate a high concentration of energy, called meltpool, that melts the metal feedstock. As a result, welds beads are stacked precisely on top of one another.

The alignment of each laser is critical so they hit the exact point where the energy is concentrated, the misalignment of the lasers leads to energy inefficiency and defects on the 3D printed parts. The camera makes the calibration process easy to follow.

Features of the Laser Calibration System:

- Accuracy: Calibrate Meltio’s multi-laser deposition head accurately and effortlessly

- Speed: Reduces calibration time by half

- Compatibility: Tailor-made software interface with portable tablet and its compatible with any Meltio system

- Packaging: Comes in a protective case that preserves maximum reliability of the accessory

- Ease of use: Simple to set up, and run. Also, the kit comes with all the necessary components you will need whether you are calibrating the Meltio M450 metal 3D printer or the Meltio Engine CNC or Robot Integration.

- Repeatability: It allows for the calibration of the lasers to be done in the exact same way every time, resulting in the same high-quality printjobs with every print.

- Traceability: The kit keeps a track of the calibration process, therefore, you can trace your steps back whenever it’s necessary.

About Meltio:

Meltio takes metal additive manufacturing to the next level by developing high-performance, affordable, and easy-to-use metal 3D printing solutions using wire LMD technology. The company’s mission is to delight customers, partners and employees by pioneering the development of affordable metal 3D printing systems that are reliable, safe, and powerful, continually reinforcing their status as disruptors.