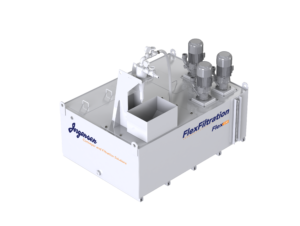

Further expanding the adaptability of its industry leading FlexFiltration, Jorgensen Conveyors and Filtration has launched new Flex B and Flex C versions for that modular coolant filtration system. The Flex B uses bag filtration, while Flex C incorporates a cylindrical/hydrocyclone filter. Both versions are built on the modular FlexFiltration design and allow shops to easily adapt their filtration to changing jobs, materials and production needs.

Jorgensen’s FlexFiltration system combines pre-engineered modules to tackle difficult coolant filtration applications. It efficiently removes fine chips and grinding sludge to achieve coolant clarity down to 10 microns or less. FlexFiltration provides coolant filtration for a variety of difficult materials including cast iron, steel, aluminum, plastic and composite materials, giving end users and OEMs alike the ability to standardize their coolant filtration process on a platform that is modular and adaptable.

The Flex B and Flex C join Jorgensen’s existing Flex G gravity filter version. Flex B provides the same flow rates as Flex G – 30, 60 and 90 gpm – and filtration down to 10 microns for most applications. As its main filtration method, bag filters make the Flex B a cost-effective method for coolant and cutting fluid filtration and ideal for CNC machine tool applications involving either single machines or centralized coolant systems.

Jorgensen’s engineers can easily incorporate bag filters into new or pre-existing coolant systems. Doing so serves as a quick, low-cost solution for removing small chips, grinding swarf and other particulate down to 10 micron nominal.

Like Flex B, Flex C also provides the same flow rates as Flex G – 30, 60 and 90 gpm – and filtration down to 10 microns at a very high efficiency.

In operation, contaminated CNC coolant enters the cyclonic filter at a high velocity through the inlet opening. The velocity of the liquid increases as it swirls downward inside the conical separating chamber. Then, solid contaminants are thrown against the walls of the chamber and forced to the bottom by centrifugal force. These solids are then discharged through a nozzle at the bottom of the filter, achieving high separation efficiency without filter media consumption.

As the whirling cleaned liquid approaches the bottom, it is unable to exit the restricted discharge nozzle. As a result, it reverses direction, forms an inner vortex and seeks the clean liquid outlet at the top of the filter. Using this hydrocyclone filtration as its main filtration method, Flex C is economically and environmentally friendly as there are no disposable medias to worry about. Jorgensen offers hydrocyclone filters in a variety of sizes to fit the volume and desired coolant clarity.

About Jorgensen Conveyor & Filtration Solutions

With over 70 years of experience in designing and manufacturing advanced conveyor, coolant filtration and material handling solutions for the machine tool, fluid filtration, metalworking, unit handling and recycling industries, Jorgensen Conveyor & Filtration Solutions offers a wide range of standard and customized systems to companies across North America and globally. All products are engineered to provide high quality, cost effective, application-based product solutions for even the most demanding environments.

For problem free production and material handling without bottlenecks caused by maintenance intensive systems, poor chip management or coolant filtration, the company manufactures reliable, innovative conveyor and filtration solutions, including MunchMan®, EcoFilter®, Filterveyor®, ShuttlePro, FlexFiltration, FlexForce, PermaClean, Will-Fill and UVS Ecologic Control® systems.

Jorgensen sets the industry standard for quality, reliability, and value for all your material handling needs.