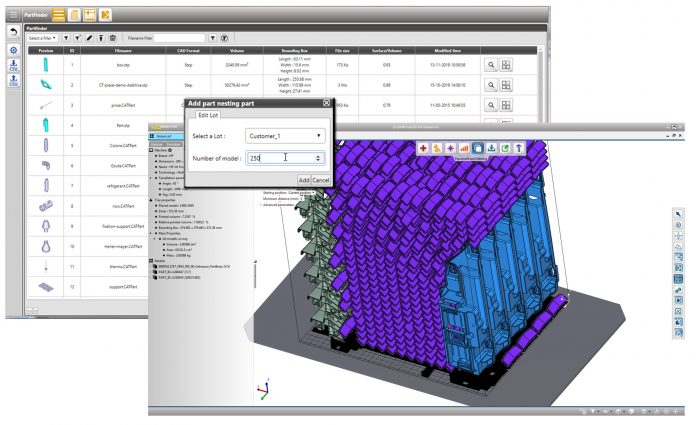

The software company CoreTechnologie GmbH (CT) presents the latest version of the renowned 4D_Additive software. The advanced version includes an innovative batch nesting tool.

With the help of the new function, the CAD models stored in the system-specific database are ordered as in a web shop and automatically sent to the printer. The arrangement and orientation of the components, the so-called nesting, automatically takes place and does not require any 3D printing expertise of the user. As a result, the usually complicated and time consuming manual operation is significantly simplified and accelerated. The system is integrated in the so-called Partfinder, which makes it possible to locate and sort suitable parts for specific processes and machine has been extended with the advanced nesting tool of 4D_Additive running in batch mode.

Optimal Results at Minimal Costs

The intelligent nesting functions with multiprocessor calculation ensure a reliable and fast automatic filling as well as the optimal utilization of the construction volume and one hundred percent collision safety. For the fully automatic orientation of the parts on the build platform, functions are available which take into account criteria such as best possible surface finish, minimum cost and space requirements as well as minimal volume of the supporting geometry. Thereafter, the iterative calculation of the alignment takes place within seconds by just selecting parts from the pre-defined database and specifying the desired quantity.

Automated batch nesting offers a great benefit especially for powder bed processes such as HP Jet Fusion, since the time saved by eliminating complex manual activities has significantly positive effects on the price per piece as well as the overall through put time of the jobs. Users only have to select and set the respective quantity of the parts in a web interface. Thereafter, the machine is filled automatically, so that an optimized number of components can be accommodated on the platforms. The relative density of a building volume can also be pre-defined allowing for a sensible heat management and in order to simultaneously optimize component quality and costs.

Additive Manufacturing of the Future

Another special feature of the trend-setting 4D_Additive Software Suite is the processing of exact B-Rep CAD data of all common systems such as Catia, NX, Solidworks, Creo, Inventor, STEP or JT. The robust B-Rep geometry kernel of the software makes it possible to test, repair and prepare the exact 3D models according to CAD Engineering Standard.

Additive Manufacturing is developing with a rapid growth and today an economically advantageous production for e.g. plastic parts of small batches is already realistic. In order to meet the increased demands of additive manufacturing and a growing need for automated workflows, the innovation company CoreTechnologie has developed the 4D_Additive Manufacturing Software Suite.

Background Information

Since its foundation in 1998, the software manufacturer CoreTechnologie with locations in Germany, France, USA, Japan and Great Britain has been led by the managing directors Dominique Arnault and Armin Brüning. With innovative products, the visionary company has consistently optimised its product portfolio and secured the technological leadership in the area of conversion software. Each year, CoreTechnologie invests more than 30 per cent of sales in the research and implementation of new technologies and has the most complete product range in this field.

In the focus of technology development is the product line of “3D Evolution” which guarantees efficient and lossless exchange of complex data structures between independent and heterogeneous CAX software solutions. With extremely powerful native interfaces for all leading CAD systems and for conversion of all common 3D formats, the software module ensures optimal interoperability of most various IT solutions.

Apart from providing visualisation and manufacturing data across most various systems, CoreTechnologie offers outstanding technologies for automatic data correction, feature-based conversion, geometry optimisation, quality control and long-time archiving as well as for visualisation of complex 3D models. The software components for software manufacturers of the most different CAX applications are the company’s second leg.

The customer portfolio of CoreTechnologie comprises more than 400 companies from the automotive, aerospace, engineering and consumer goods industry who are in many cases the quality leaders in their relevant segment.