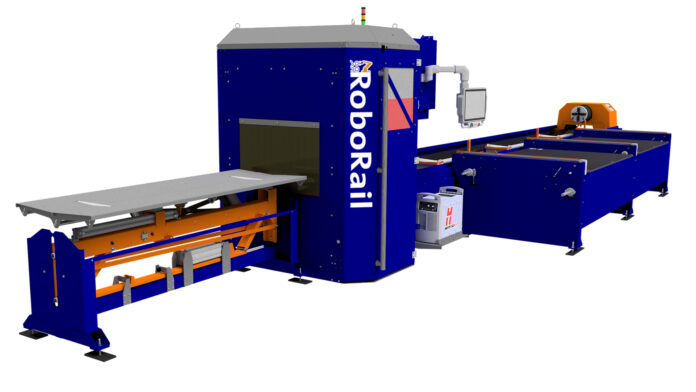

HGG Profiling Equipment BV, a leading manufacturer of cutting and profiling equipment for the welding industry, will be exhibiting its ProCutter 900 RB Pipe Profiler in Booth B13051 at FABTECH 2023, held September 11-14 at McCormick Place in Chicago, Illinois. The recently introduced RoboRail robotic plasma cutting machine will be featured in partner Automated Layout Technology’s Booth A5716. The ProCutter 900 RB integrates the proprietary ProCam software for 3D parameter-based part profile programming for perfect fit-up. A three-jaw chuck for secure pipe positioning, durable pipe support, and a cutting bed equipped with a roller bed offer easy pipe loading and unloading. Available with a cutting trolly with biaxial cutting head for efficient oxy-fuel plasma cutting, the system’s easy-to-use operator interface with touch-screen navigation simplifies the training process.

The RoboRail has been proven to significantly reduce profile cutting time by up to six hours in some applications including pipe for railings, channels and other miscellaneous parts. The compact robotic machine’s ability to take designs directly from 3D SDS/2, TEKLA, STEP, and other CAD files ensures the most accurate cutting performance for channels, tube columns and angles up to 8-in. x 8-in., and 1 ¼-inch pipe. The Hypertherm plasma cutting system processes handrail pipe, stringer channels, box tubes, angles, etc., with ease.

At the show, HGG will feature the Imperial measurement version of the RoboRail system, which features an infeed length/weight up to 882 lbs and outfeed length up to 8-feet maximum with an outside diameter of 10.79 inches and minimal flat bar thickness of 0.40 inches. One customer reduced pipe profile cutting time from several minutes manually to 30 seconds after adopting the automated RoboRail system, including layout and marking. The system’s cutting accuracy eliminates the need for grinding and sawing and shaves significant time off welding processes. Visitors to the booth will be able to speak with automated 3D plasma cutting experts who will be available to discuss additional automated 3D profile cutting systems suitable for virtually any industry.

Represented exclusively in the U.S. by Automated Layout Technology, RoboRail is suitable for supplementing larger capacity machines for added processing flexibility to cut copes and cut-outs quickly and accurately in angle, single-story tube columns for strip malls or mezzanines, bolted stairs, and 8-in. or 10-in. structural pipe.

More About HGG

HGG Profiling Equipment’s commitment to offering its customers the freedom to create is evident in the quality 3D profiling machines that provide complete flexibility to cut complicated profiling in steel pipes, beams, box sections and other profiles regardless of size and specifications. Founded in 1984 in Wieringerwerf, Netherlands, HGG has become the world leader in steel profile cutting with expertise gleaned from years of subcontracting 3D profiling services which typically handle roughly 250 tons of material per week. The company’s machines are capable of cutting every type of steel, with the exception of plate, and can be found in nearly every type of shop including those serving offshore oil and wind, steel construction, process piping, shipbuilding and more.