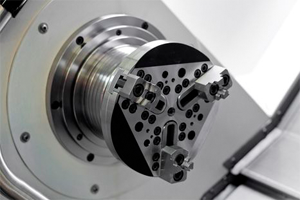

Hainbuch presents a jaw module that is small and flexible, that can be quickly changed, and that covers a large clamping range. The result is a quick-change clamping solution for all situations. Mandrels and clamping heads can also be used in the basic unit. The new jaw module completes the circle and gives a new clamping dimension that opens up even more possibilities for users. All this with less weight and a smaller interference contour. In short: ID clamping, OD clamping and jaw clamping all-in-one.

The Hainbuch solution, consisting of a chuck and a jaw module, has nothing in common with the large, heavy, energy sapping big jaws that can be found in many machine shops, where their size is more of an obstacle than an advantage. These heavy chucks put load on the machine spindle and are slow to accelerate and decelerate, losing time and using energy. This takes longer for the part to be produced and hence makes it more expensive and also wears the machine bearings out more quickly. This is squandering of energy and piece rate time in its purest form. Naturally these are costs that today no one can afford or want to pay. Let’s assume that someone purchases a lathe/milling machine with spindle taper DIN A2-6 65mm bar capacity, here the workpiece range is usually diameter of 10 to 200mm. To cover that range, a machine with a 215 jaw chuck is purchased. However 80 percent of the components are in a clamping range of 100mm and smaller. And here the dilemma arises that in practice you have to cope with daily: Large clamping device, small workpiece. It is difficult to get all of the tools in place, often the tools will not reach center line and often special tools are required with longer reach, increasing

The Hainbuch solution, consisting of a chuck and a jaw module, has nothing in common with the large, heavy, energy sapping big jaws that can be found in many machine shops, where their size is more of an obstacle than an advantage. These heavy chucks put load on the machine spindle and are slow to accelerate and decelerate, losing time and using energy. This takes longer for the part to be produced and hence makes it more expensive and also wears the machine bearings out more quickly. This is squandering of energy and piece rate time in its purest form. Naturally these are costs that today no one can afford or want to pay. Let’s assume that someone purchases a lathe/milling machine with spindle taper DIN A2-6 65mm bar capacity, here the workpiece range is usually diameter of 10 to 200mm. To cover that range, a machine with a 215 jaw chuck is purchased. However 80 percent of the components are in a clamping range of 100mm and smaller. And here the dilemma arises that in practice you have to cope with daily: Large clamping device, small workpiece. It is difficult to get all of the tools in place, often the tools will not reach center line and often special tools are required with longer reach, increasing

vibration and losing accuracy. Also there is a high risk of collision.

Hainbuch modular solutions use a simple formula: Small workpiece = small clamping solution. Using the new small jaw module, about 80 percent of usual components are covered, and for larger components it can be easily changed over to a large jaw module within 30 seconds. The basic unit is a Spanntop chuck or Toplus chuck, now accepted as an excellent workholding device in its own right. Add to this the jaw module, clamping heads and mandrels; you achieve reliability, accuracy, and safety that traditional jaw chucks lack, especially for ID clamping. Advantages include a simple modular system for fast clamping to a clamping range of 200mm; availability in two sizes (144, with clamping range from 25–115mm and 215, with clamping range from 25–200mm); minimal interference contour; proven technology; optimal utilization of the jaws; flexible, fast and repeatable set-up on clamping head or mandrel clamping; rigid workpiece clamping through the use of clamping head or mandrel; full bar size passage when using the clamping head; suitability for sensitive clamping and delicate components; option to be used as a pick-up chuck on sub spindles; ease of maintenance; resistance to contamination thanks to guideway seal and suitability for stationary use.

For more information, please visit:

www.hainbuchamerica.com

or contact:

sales@hainbuchamerica.com