Fronius continues to draw on the advanced technical capabilities of its latest product range with four new arc variants for the TPS/i MIG/MAG welding platform: the LSC Root and LSC Universal characteristics supplement a new algorithm and feature reduced spatter and greater arc stability. New welding parameters form the basis for functions available in the industry for the first time, such as the penetration stabilizer. In addition, Fronius has again made a significant improvement to its proven arc length correction and dynamic correction functions. The advanced versions of LSC Root and LSC Universal permit, with the aid of special hardware, the use of longer hosepacks whilst maintaining consistently high welding quality. All these innovations make the operation of the power source significantly easier and guarantee the best welding and brazing results, even for less experienced welders.

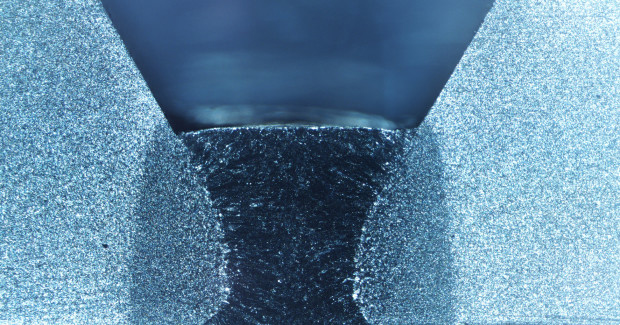

Fronius has developed a completely new algorithm for LSC (Low Spatter Control). It makes effective use of the high computing power, large memory, extremely fast system bus and highly dynamic wire feed speed of the company’s latest MIG/MAG welding platform to ensure an extremely stable and low spatter arc.

Particularly noticeable are the advances in root pass welding, for which LSC Root was developed. LSC Root guarantees excellent root formation and a high deposition rate with reduced energy input. Unlike conventional MAG welding, it is now for the first time possible to perform vertical down welding without having to accept poor fusion results. This makes the root pass significantly easier for users. Furthermore, shielding gas loss has been reduced by up to three percent thanks to a new generation of welding torches.

The LSC Universal arc characteristic is especially suited to the welding of fillet welds, corner welds, lap joints as well as filling and capping runs and brazing.

LSC arc users benefit from the new penetration stabilizer. When activated, it keeps the fusion penetration constant during stick out fluctuations with the help of a new wire feed speed control, which can be adjusted as required by the user. This has a particularly positive effect on fillet welds that are to be welded in the vertical up position with an oscillating motion. The stabilizer ensures a constant and deep fusion penetration, even in the event of external interference. Very good results can be achieved even with lower cost solid wires.

Moreover, Fronius has enhanced some functions that are already supported by predecessor devices and appreciated by welders – arc length correction and dynamic correction. For example, the arc pressure can now be set via the dynamic correction in LSC Root.

Improved functions that ensure high seam quality at the problematic start and end of welding round off the LSC package.

To enable the use of the longer hosepacks that are commonplace in, for example, pipeline and container construction and robotic welding, Fronius has developed some additional hardware that – without compromising quality – reduces the negative influence of increased inductance in the welding circuit. The advanced versions of the LSC Root and LSC Universal arc characteristics are available for appropriately equipped power sources.

About Fronius International GmbH

Fronius International GmbH is an Austrian company with headquarters in Pettenbach and other sites in Wels, Thalheim, Steinhaus and Sattledt. With 3,344 employees worldwide, the company is active in the fields of welding technology, photovoltaics and battery charging technology. Around 92% of its products are exported through 20 international Fronius subsidiaries and sales partners/representatives in over 60 countries. With its innovative products and services and 1,008 active patents, Fronius is the global innovation leader.