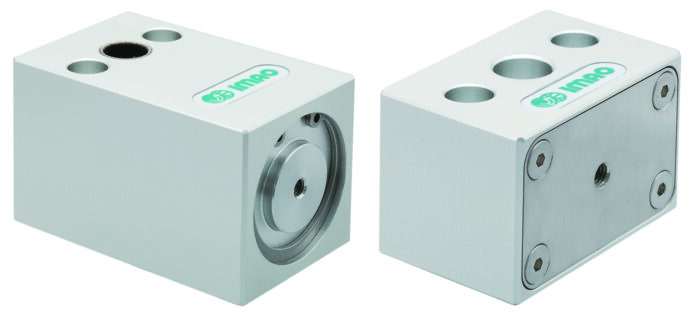

The compact version, identified as PSLC-L, comes in both low (0.3MPa) and standard pressure (up to 0.7 MPa) and can accommodate shaft diameters as small as 8 mm. Sizes of the clamps vary from 55 to 63 mm in length, with operating air pressures 43 to 100 lb., and sliding loads of 11 to 31 lb. The body is made from 5052A aluminum. The clamping shaft is made from 5052A anodized aluminum.

The heavy-duty version, identified as PSLC-M, also provides secure clamping of sliding shaft and spindle after position adjustment of parts and units in the machinery. It is suitable for diameters between 10 and 30 mm and is available in lengths of 80 to 130 mm. Torque holding pressure on these heavy-duty shaft clamps range from 4 to 29 lb. and sliding loads to 495 lb. Brackets, identified as PSLC-M-S type, for the heavy-duty version, are available to mount a sensor and can be used in combination with sensors supplied by the user to detect the clamping condition. Pneumatic clamp body and cover are made from 5052A anodized aluminum. The clamping shaft is made from 1045 steel with an electroless nickel-plated finish.

Positive pneumatic shaft-locking clamps are designed for quick change applications. They provide secure clamping of sliding shaft and spindle after position adjustment of parts and components in the machinery. Spring clamping occurs when air is removed, and unclamping when air is provided. Spring clamping and pneumatic unclamping mechanism prevents the decrease of clamping force by air leakage.

In addition to shaft locking clamps, Fixtureworks offers other quick change pneumatic clamping fasteners, quick action spring plunger clamps, handle and levers, knobs and grips, equipment handles, hand wheels and cranks, hinges and latches, leveling supports, industrial rubber bumpers, stops and wheels, fixture clamps, clamping locating systems, work positioning elements, vises, grippers and mechanical linear actuators.