Please join Bystronic at Booth B7229 during FABTECH 2018 in Atlanta, as they demonstrate new and innovative high-performance solutions that cover the full spectrum of file-to-part manufacturing: laser cutting and bending machines, automation, and software technologies that are connecting and driving fabrication companies to new levels of productivity, profitability and success.

Bystronic will present a new fiber laser platform equipped with powerful ByVision Control and other innovative features you have come to expect from this industry-leading manufacturer. In addition, Bystronic’s ByFinances will offer highly competitive and innovative financing options that make owning a Bystronic a reality.

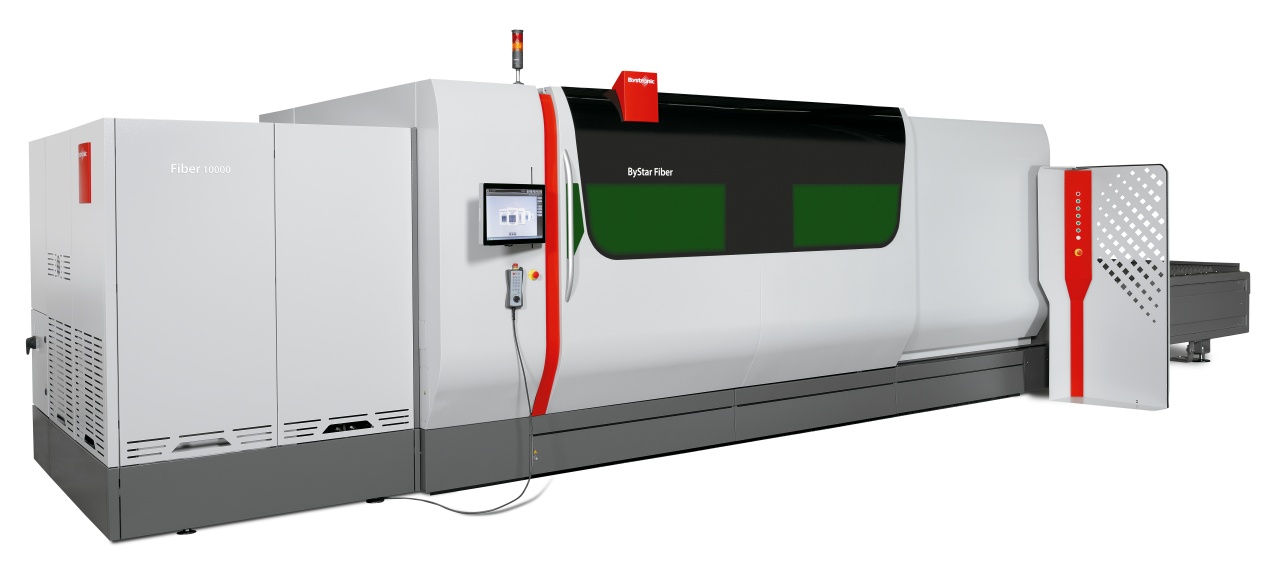

Innovation is at the core of the ByStar Fiber laser machine with 10kW Fiber laser which has been designed 100% to meet the demands from high-speed Fiber laser cutting as well as cutting capabilities into the thick plate range. High machine dynamics and process reliability ensure uncompromising high-end performance, the highest parts output, and premium cutting quality. The ByStar Fiber 3015 Fiber laser machine will be shown with the ByTrans Extended automated material load/unload system.

Smart, precise, profitable and easy-to-use, the Bystronic Xpert 150 press brake with revolutionary Bystronic ByVision Bending control, pressure reference technology, automatic dynamic crowning and 6-axis back gauge system offers unmatched efficiency and productivity capabilities and the highest repetition accuracy on the market. The Xpert 150 is the only press brake that introduces no angle errors itself with a ram positioning accuracy of .00015” inch.

The Xpert 40 with Mobile Bending Robot supports today’s fluctuating lot sizes and varying part complexities in a fully flexible automated or manual bending system. Control is seamlessly integrated into the press brake user interface. The robotic system can be set up when and where you need it in just a few minutes.

BySoft 7 software represents a new generation of design and manufacturing software that keeps pace with high productivity downstream equipment. BySoft 7 offers a comprehensive range of programming functions for easily designing parts, converting from existing CAD files, and creating cutting plans and bending programs. Embedded cost calculator can determine actual production costs. With Plant Manager, manufacturing processes are scheduled and monitored efficiently providing an overview of the production process.

The Bystronic MES is a new software solution that creates digital transparency across the entire process chain of sheet metal products. MES allows users to plan, direct and evaluate work flows according to defined timelines.

Developed by Bystronic, ByCockpit provides real-time analysis and visualization of the data associated with sheet metal processing. ByCockpit visualizes selected key indicators regarding machine performance and manufacturing efficiency, enabling companies to constantly improve their production.

About Bystronic

Bystronic is a worldwide supplier of high-quality press brakes, lasers cutting systems, automation and software for the economical processing of sheet metal and tubes. Bystronic stands for reliability, high-performance innovation, an outstanding price-performance ratio, and user-friendly operation. The focus is on the automation of the complete material and data flow of the sheet metal cutting and bending process chain. The company’s North American headquarters is located in Elgin, IL. Offices are also located in Toronto, Canada and Monterrey, Mexico.