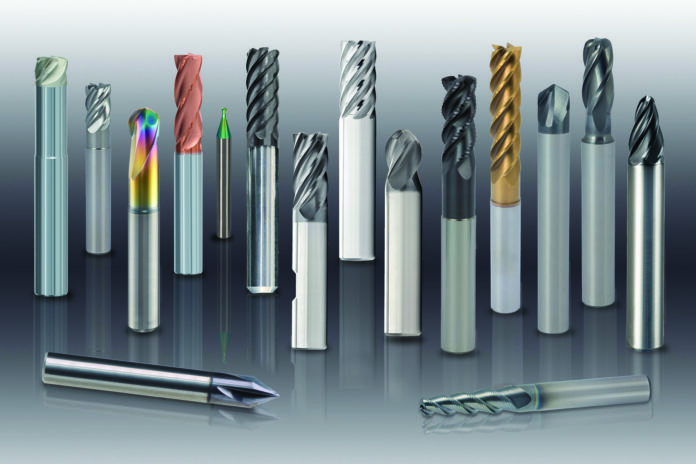

EMUGE-FRANKEN USA, a leading manufacturer of high-performance end mills, taps, thread mills, drills, and other rotary tools, announced it has significantly expanded its line of end mills, adding nearly 2,500 new tools for a total of over 6,000 end mills now available as standard offerings.

“We are committed to providing our North American customers with an extensive range of high performance solid carbide end mills to best suit their applications,” said Mr. Craig Gosselin, Milling Product Manager. Ever since its foundation, Franken, as part of the EMUGE-FRANKEN Company, has been developing and manufacturing high precision milling tools in Germany. Also, end mill manufacturing is now being expanded at EMUGE FRANKEN USA headquarters in West Boylston, Massachusetts, where its TOP-Cut VAR line and Chamfer Mills are made.

The extensive portfolio of EMUGE-FRANKEN End Mils includes eleven tool categories which were expanded to address an even greater range of milling requirements. The following details the significantly expanded lines and new tool types:

- Industry’s most versatile variable helix carbide tool solution, TOP-Cut VAR End Mills have increased three-fold to comprise over 1,200 tools which are manufactured in the U.S.A. to stringent EMUGE-FRANKEN Germany specifications. Featuring unique geometry and coating, TOP-Cut VAR end mills are as effective in multiple job shop applications as they are in challenging production cutting operations. The TOP-Cut VAR line is now available in 4, 5, 6 and 7-flute configurations, with or without corner radius, and ball nose, stub, standard and long length inch sizes. In addition, EMUGE-FRANKEN USA can provide custom variations or tool modifications of TOP-Cut VAR mills.

- TOP-Cut Metric End Mill line has been expanded for universal milling in both roughing and finishing operations including 2, 3, 4, 5 and 6-8 flute configurations, with or without corner radius, and ball nose, mold and die, torus and coolant-fed types.

- Solid Carbide Chamfer Mills are now available in an increased range of helical types as well as new engraving and counter sinking tools. For optimum performance, chamfer mills are used in a milling pass and not as a plunging tool to quickly mill linear chamfer angles and create chamfer angles for threaded holes.

- New Cera-Cut End Mills are premium ceramic milling cutters developed for machining heat-resistant super alloys, combining EMUGE-FRANKEN’s unique Duplex geometry and brazed ceramic head design to dramatically reduce machining time on high nickel alloys.

- New High-Precision Skiving Tools are designed for skiving which combines gear hobbing and gear shaping for internal and external gears, splines and more.

Coinciding with the end mill line expansion, EMUGE is offering a new, comprehensive 240-page “Catalog No. 430” which provides details and specifications about EMUGE-FRANKEN High-Performance, Solid Carbide End Mill Solutions with illustrations, technical drawings, product descriptions, cutting data and technical information. The new print catalog is free by request – click here to order (select catalog and click on “Order Catalog” in upper right on your screen) or to view online in a digital flipbook format click here.

About EMUGE-FRANKEN

For over 100 years, the German company group EMUGE-FRANKEN has been one of the world’s leading manufacturers of precision tools for thread cutting, drilling, gaging, clamping, and milling. With 1,950 employees, EMUGE-FRANKEN offers an innovative product program with 40,000 in-stock items and a multiple of that with customer-specific tools. The product range focuses on applications in the automotive industry, power generation, aerospace industry and medical technology as well as general manufacturing. As a complete system supplier for the machining industry, EMUGE-FRANKEN has branch offices or sales partners in 52 countries.

EMUGE-FRANKEN USA is a wholly-owned subsidiary of the 1,950 employee German company EMUGE-Werk Richard Glimpel GmbH & Co. KG (Lauf, Germany). EMUGE-FRANKEN USA offers end-user technical support through a network of in-the-field engineers and in-house product specialists, all with extensive tooling and application experience. Over 10,000 types of cutting tools and accessories are stocked in the company’s U.S. and Canadian Headquarters located in West Boylston, MA, U.S.A. which includes a technology center with a machining and tooling demonstration showroom and classroom, tool manufacturing and coating, reconditioning, warehouse, sales, support, and administrative offices.