E-Z LOK, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood, just announced it will begin to build out a portfolio of both pull-out and torque out test data for the inserts it offers. The announcement was made by Kyle Lindsly-Roach, Director of Sales & Marketing at the company’s Gardena, California headquarters.

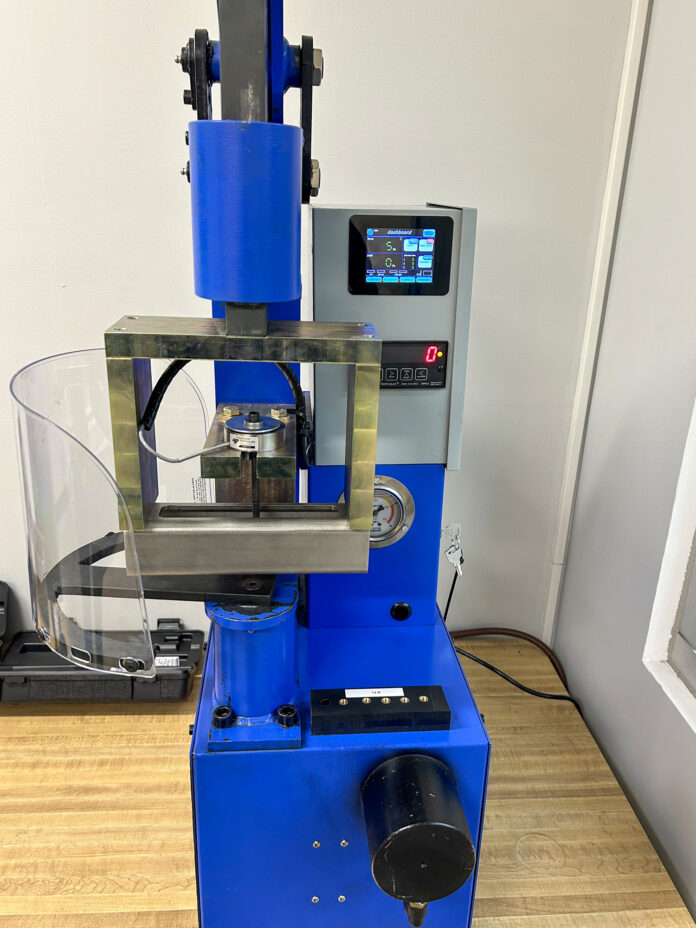

The company’s initial plan was to use a third-party lab to test the performance of inserts in various materials. However, E-Z LOK ultimately decided it would be more cost effective and beneficial if they brought the testing equipment in-house because it allows them to complete testing at their own pace, as well as perform testing on future products. This decision was made in the first quarter of 2024 as a way for the company to build a more complete library of test data for their users. Carver Engineering/Labs in El Cajon, California is building the machines, which are up and running at E-Z LOK as of early October 2024.

Insert pull-out strength is tested by installation in various test blocks of materials (plastic, wood or metal) and threading a bolt into the insert. Then, the bolt is pulled upwards until the insert is pulled out of the material. The insert testing machine records the value. The torque out machine measures the torque the insert can withstand before spinning out of the material, breaking the fastener or stripping the threads of the insert.

Available on the E-Z LOK website, the data will be housed under the “Resources” section with links for specific product groups. Additionally, the company will create PDFs of the testing data on a product group basis.

Commenting on its significance, Kyle Lindsly-Roach, Director of Sales & Marketing said, “It is a great resource that helps engineers and customers who are designing bolted joints, and want to know the approximate pull-out and torque values they could expect to see in their applications.”

About E-Z LOK

E-Z LOK is a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood. Inserts for metal include solid wall and helical wire-thread inserts, while inserts for plastic feature press-in and ultrasonic/heat stake designs. Those for wood are die cast zinc alloy hex drives for softwood and brass knife threads for hardwood. A variety of kits for the above inserts are available and feature installation tools, drill bits, etc.

E-Z LOK is a third- generation family owned and operated company. Founded in 1956, it primarily sells through local, regional, and national industrial distributors.