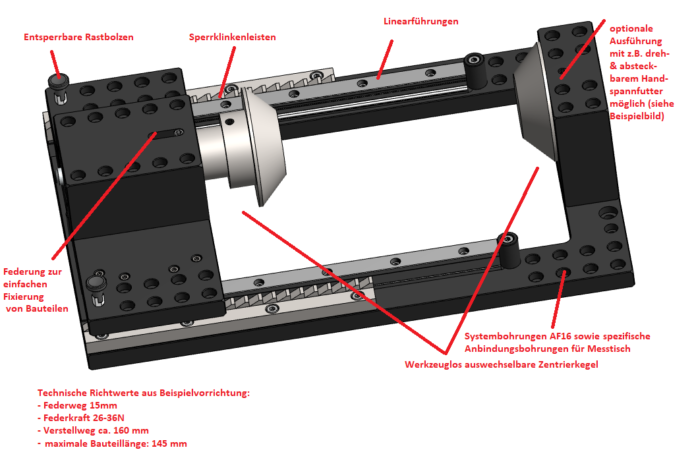

The core of the innovation is the extremely easy-to-handle spring system for holding and fixing the components to be measured. Centering cones that can be replaced without tools adapt to different diameters – even hollow shapes, such as pipes. Optional versions also allow the combination with, for example, an ALUFIX hand chuck that can be rotated and staked out. The spring force, which can be adjusted from 26 to 36 newtons, keeps even heavier workpieces safely in position.

The adjustment range of the new 160 mm combination measuring fixture enables objects with a component length of up to 145 mm to be accommodated. The adjustment to the workpiece length is carried out extremely conveniently via the slide, which can be moved and locked by means of locking bolts via pawl rails and linear guides.

The combination measuring fixture, which is assigned to the modular clamping system ALUFIX by Witte, has system holes compatible with the ALUFIX size AF16 – the construction on the respective measuring table can also be realized thanks to a specific connection hole pattern.

Devices and measuring setups realized with ALUFIX are reliably reproducible. The consistent implementation of the modular system allows unlimited, long-term multiple use of virtually all standard elements installed in fixtures.

About Witte Barskamp

Founded in 1969 as a production partner for high-precision components in the aerospace industry, Witte Barskamp GmbH & Co. KG is today one of the leading international developers and manufacturers of modular clamping, positioning and measuring fixtures as well as feeder systems. With the ALUFIX mo dular fixturing system and the versatile vacuum clamping systems, Witte is considered the global market leader.