With the caliTEST-B, Kistler presents a smaller, more cost-effective alternative to the established caliTEST calibration device for torque wrenches. It enables the calibration of torque wrenches or tools with an effective length of up to 1,320 mm according to DIN EN ISO 6789. In developing the caliTEST-B, the measurement technology expert paid particular attention to user-friendliness and flexibility, so that screwdriver-shaped torque tools can also be calibrated quickly and easily.

Whether in aeroplanes, cars or steel constructions: we trust the components that hold the individual parts together with our lives. To ensure the safety of bolted connections, specific standards cover both the testing of fasteners and the associated tools. These include DIN EN ISO 6789, which describes the regular calibration of torque wrenches.

For years now, Kistler has offered the caliTEST, a special calibration device for torque wrenches, to minimize the impact of calibration on ongoing operations. It is a popular option, particularly for larger companies with many torque tools and their own calibration laboratory. However, for medium sized companies or those using a smaller number of tools, such a calibration device is usually not worth the investment. This means they have to send the torque wrenches to specialised laboratories in order to have the calibration carried out there. Kistler now offers an alternative for this customer group, the caliTEST-B. The small, cost-effective brother of the large laboratory test bench enables reliable calibrations in the range from 2.5 to 500 N·m. If required, the calibration range can also be extended to 0.2 to 1,000 N·m. Alongside the calibration in accordance with DIN EN ISO 6789, tool-related machine capability testing in accordance with VDI/VDE 2645 is also possible. The display deviation of the calibration device is less than or equal to 0.5 percent for the measured value.

Calibrate different wrenches with one flexible solution

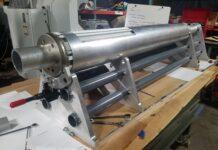

Similar to the large calibration device, the caliTEST-B consist of a mounting device for the torque wrench, a drive unit with torque sensor, measuring and control electronics and an evaluation system. Unlike the existing caliTEST, which covers a particularly wide measuring range with several holding devices, the sensors in the caliTEST-B can be exchanged for different torque ranges. Users do not have to compromise on flexibility. An equivalent device for longer tools is available as well. Options include a special holder for the screwdriver-shaped torque wrenches, a barcode reader and a label printer. These latter options allow for checked tools to be quickly recorded and labelled in the system as part of everyday work.

User-friendly operation for total process reliability

For process reliability, Kistler relies on the convenient CEUS software for the caliTEST-B calibration. The web-based program allows users to integrate individual limit values, specifications and tolerances into the evaluation. In addition, the different values and settings for the respective tools can be easily saved for particularly convenient use. The program then guides the user step by step through the measurement process and generates an individual measurement history for each tool. CEUS automatically saves the test reports so that they are quickly available when needed. To ensure that calibration is carried out quickly and smoothly in accordance with the standards, Kistler offers appropriate user training courses.