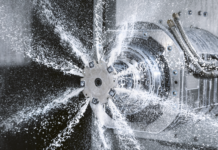

Bunting® Magnetics Co.—producer of precision magnetic products for the worldwide recycling, food, printing, automobile, plastics, and electronics industries—has introduced a new line of high-intensity separation conveyors. The first public showing of the product line will be in Booth 4667 at WasteExpo 2013 in New Orleans, May 21-23.

Bunting Product Manager Don Suderman, discussing the new conveyor line, said: “These new separation conveyors are designed to provide extremely high magnetic fields, which enable removal of lightly magnetic tramp metal fines. High-intensity magnetic fields also separate work-hardened 300 series stainless steel from the product stream, increasing separation effectiveness for medical waste, as well as automotive and electronic scrap recycling. Optional vibratory feeder trays are available. The conveyor frames are constructed of 300 series stainless steel, and tough urethane endless belts maximize magnetic field exposure to the material being conveyed.”

For more than 50 years, Bunting Magnetics Co. has developed and manufactured precision magnetic products for the worldwide printing, automobile, plastics, food, electronics and recycling industries. Bunting Magnetics Co. products serve global markets and include a broad range of magnetic materials and components, magnetic separation systems, material handling equipment, magnetic printing cylinders, metal detection equipment, bonded magnetics, and assemblies. Bunting manufacturing facilities are located in Newton, Kansas; suburban Chicago, Illinois; DuBois, Pennsylvania; and Berkhamsted, England.

For additional information, please visit:

buntingmagnetics.com

or call:

+1-316-284-2020