CNC Broach Tool is the leading provider of inserted broaching tools and carbide broach inserts. While other companies offer broaching tools that use high-speed steel (HSS) inserts, CNC Broach Tool’s carbide inserts provide a longer tool life and superior finishes, making them the best choice for broaching splines and keyways in Haas CNC machines.

With CNC Broach Tool’s carbide inserts, customers can create perfectly indexed broached features in their Haas CNC machines. This is particularly useful when orientation is required for the broached spline or keyway, as it can be machined in the same operation as other features. This reduces setup time and ensures that all the features are in perfect alignment with each other. This not only improves accuracy but also reduces the chance of error, saving time and money in the long run.

CNC Broach Tool’s inserts have yet another unique design advantage over their competitors. While other companies offer inserts with only one cutting edge, CNC Broach Tool’s inserts have two cutting edges. This means that when one edge dulls, the broaching insert can be rotated to bring a fresh edge into use, extending the life of the tool and reducing downtime for tool changes.

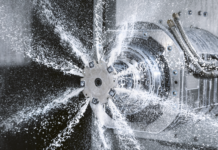

CNC Broach Tool offers a wide range of inserts for various applications with 38 stock sizes ranging from .041″ up to .752″ wide.

By choosing CNC Broach Tool’s two-sided TiN coated carbide inserts, Haas machine owners can expect to increase their efficiency and productivity, reduce downtime, and save money in the long run.