Travel through time with BOGE: S-4 OPTIMUS: the screw compressor of the future

What if…? Every innovative development starts with unbridled creativity at BOGE  Kompressoren. This is no less true of the S-4 OPTIMUS design study. As a system provider of compressed air solutions with the belief that “everything is possible,” we are already testing the technologies that will dominate the market in the future. We are aiming to optimize and further develop the design of the successful S-4 screw compressor. Our focus is on cost efficiency, ease of maintenance and quiet running.

Kompressoren. This is no less true of the S-4 OPTIMUS design study. As a system provider of compressed air solutions with the belief that “everything is possible,” we are already testing the technologies that will dominate the market in the future. We are aiming to optimize and further develop the design of the successful S-4 screw compressor. Our focus is on cost efficiency, ease of maintenance and quiet running.

“Our S-4 series already leads the field in terms of its energy efficiency and ease of maintenance. Furthermore, it is less than half as loud as previous models,” says Frank Hilbrink, Product Market Manager at BOGE. “However, our company is driven by innovation and so we’re always striving to excel ourselves“. The S 76-4 LF OPTIMUS is the testing ground for future fine-tuning in the oil-lubricated screw compressor series. There is huge demand for this type of equipment in applications where cost efficiency, consistent process reliability and high quality of compressed air are key factors. Examples include the oil, gas and chemicals industries, paint shops in the automotive industry, for instance, and metal processing.

Initiative for future technologies

How can we make the use of screw compressors even more convenient and attractive for the customer? In answer to this question, maximum operational reliability and a need-based use of resources form part of the S-4 OPTIMUS design study. One technical approach might, for example, be an oil circuit without a thermostatic valve. This would reduce maintenance and increase the reliability of the compressor. BOGE is also testing how controlling the amount of oil injected could optimise efficiency of the airend at every operating point and in every application. Furthermore, BOGE has worked out how to increase machine connectivity using technologies that have long lost their “nerd factor” amongst consumers: WLAN or Bluetooth, for example, can be used for integrated wireless control. This would mean less wiring, and other accessory devices could be easily connected.

Length: 2,127 characters including spaces

Status: 14 July 2017

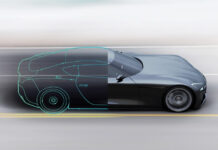

Image: 3D model of an S-4 OPTIMUS, source: BOGE KOMPRESSOREN

About BOGE Compressors

BOGE America is the USA based America’s subsidiary of BOGE KOMPRESSOREN Otto Boge GmbH & Co. KG based in Bielefeld, Germany. Whether for centrifugal compressors, screw compressors, high-pressure piston compressors, scroll compressors, controls, air treatment equipment, complete systems or individual devices, BOGE meets the most diverse requirements and highest standards – in a precise and customer oriented manner. BOGE solutions are used by all sectors of industry to supply compressed air for a wide range of manufacturing processes. The USA Operations of BOGE America stocks the various technologies of high-quality compressors and spares for immediate support to needs. Compressed air systems are designed, sold and serviced through a dedicated network of over 50 distributors in North, Central, and South America. The USA Operations is also the “Center of Excellence” for Technical Trainings for our partners to ensure Top Level Support for the consumer. For more information, visit www.boge.com/en