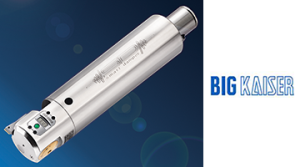

BIG KAISER introduces the EWN & EWD Smart Damper – precision boring heads with a patented damping system to eliminate vibration in deep-hole finish boring.

The integral design of these new heads shortens the distance from the damping mechanism to the cutting edge, which is the source of vibration. This produces higher damping effects to the tool assembly to minimize the chatter or vibration – thus achieving better surface finishes and improved metal removal rates.

The integral design of these new heads shortens the distance from the damping mechanism to the cutting edge, which is the source of vibration. This produces higher damping effects to the tool assembly to minimize the chatter or vibration – thus achieving better surface finishes and improved metal removal rates.

“For precision machining of deep bores, it had previously been necessary to program low cutting parameters in order to prevent vibrations, which unnecessarily increases machining time”, says Jack Burley, VP Sales & Engineering of BIG KAISER. “The EWN/EWD Smart Damper overcomes this problem, and enables high cutting parameters to be used. This means that extremely short turnaround times can be achieved, which improves productivity by up to a factor of ten.”

Our tests have shown that deep holes free of vibration can be bored with an excellent surface finish with dramatic time savings. For example, with a projection length of 14.3” working with high-carbon steel at a cutting speed of 1,300 SFM, an impressive feed rate of 11.4 IPM was achieved with the EWN41 Smart Damper.

The newest Smart Damper solution is either equipped with the tried-and-true EWN analog boring head series, or the latest digital technology in the EWD series. The EWN heads feature a dial with Ø.0005”/div setting accuracy (.0001” w/ Vernier). The EWD heads have a large digital screen, which clearly shows adjustments to an accuracy of Ø.00005”, thus helping to minimize operator errors and removing the need for complicated Vernier markings. The digital display can be reset to zero at the push of button and has an auto power off function, while the current position of the cutting edge will be shown automatically again due to direct path measurement when the tool is switched on.

The new Smart Damper is compatible with BIG KAISER’s modular CK/CKB system, which means that the length of tool combinations can be freely selected up to a maximum of ten times the diameter, and are capable of being ran on nearly every major spindle interface. All tools are coolant-through, and thanks to three different insert holders per head size, an extraordinary boring range is possible. For example, the EWN and EWD68 heads can bore a range of Ø2.677”-5.906”. For additional peace of mind, all BIG KAISER EWD heads have a seal rating of IP 69K – the highest possible.

To view a PDF of the catalog or to order a hardcopy, visit www.bigkaiser.com, where you can also learn more about the entire Smart Damper system which features integral damping shanks for face mills and CK/CKB boring heads, modular damping extensions for CK/CKB boring heads, and modular damper heads for inch and metric face mills.

BIG KAISER is a worldwide leader in high-precision tooling systems and solutions for the metalcutting industry that guarantee extreme accuracy and repeatability. Our products are of the utmost quality — manufactured with materials and craftsmanship that enable superior performance. As a member of the BIG DAISHOWA Group (Osaka, Japan), BIG KAISER has grown into a well-recognized global tooling provider, with manufacturing facilities in North America, Europe and Asia.

For more information, contact BIG KAISER, Hoffman Estates, IL at 224-770-2999, e-mail bigkaiser@us.bigkaiser.com or visit www.us.bigkaiser.com.